lugged butterfly valve

butterfly gate valve

sanitary butterfly valve

butterfly valve dimensions

Oftentimes, people

are unaware that there are numerous types of ball valves.

First, the

distinction between full port versus reduced port illustrates one of the big

differences.

A full port

valve has the same internal diameter as the pipeline into which it is being

installed.

(e.g. a 3/4”

full ported ball valve has the same internal diameter as a 3/4” pipe.)

A reduced

port ball valve, also commonly referred to as a standard port valve, has the

internal diameter of one pipe size lower. (e.g. a 3/4” reduced ported valve has

the internal diameter of a 1/2” pipe.) It is especially important to understand

this concept when valves get much larger in diameter. There can be significant

cost savings derived from going with a reduced ported valve if the application

allows you to do so. As you can well imagine, an 8” reduced port valve, which

has the internal diameter of a 6” pipe, will be significantly less expensive

than an 8” full port valve.

In addition

to the aforementioned differences in porting, ball valves also come in one-piece,

two-piece, and three-piece configurations. All these styles would be available with

either full or reduced ports. A three-piece

valve, just as the name implies, has three main pieces that make up the valve:

a center section and two end sections.

The center section houses the ball, stem, and valve seats. The two end sections provide the piping connections

and are typically offered in threaded, socket weld, or butt weld options. These

end connections can be removed from the valve’s center section and independently

installed into the piping system. These

end connections act like a union, otherwise known as a ground joint union. These unions, or end pieces, on a three-piece

valve enable the pipe fitter to install the valve in the piping system at the

point of service. Three-piece ball valves are usually more expensive than one

or two-piece ball valves. However, when

using one or two-piece valves, you must still budget for the installation of

unions upstream and downstream of the valves themselves. Often, the additional costs for unions and

the labor to install them outweigh the incremental increase in price when using

a three-piece valve.

Also, when

evaluating the overall cost of an installed valve, things like unions and required

pressure ratings can weigh heavily on the bottom line. (e.g. a 600# rated valve

will cost far less than a 1000# or 2000# rated valve.) It’s important to consider these aspects of your

application(s) prior to choosing or specifying a particular valve.

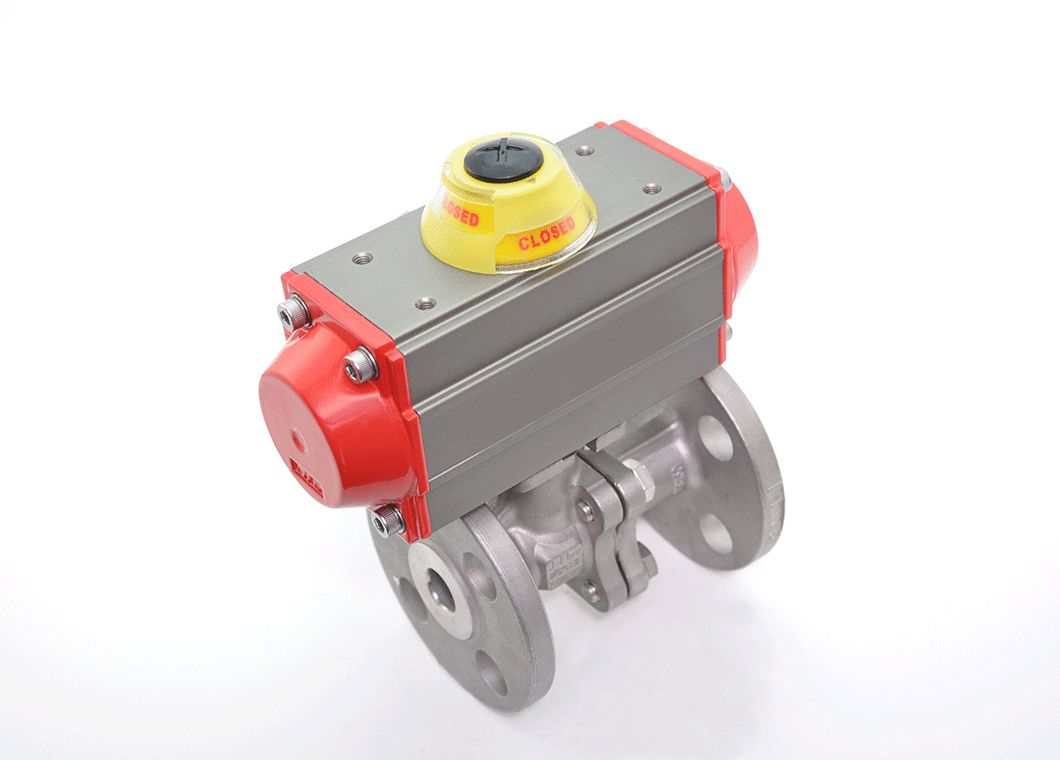

Finally, another

cost consideration when making your selections is whether you will be automating any of the valves that will be installed. If automation remains a

possibility in your future plans, you should seriously consider opting for a

valve with an actuator mounting pad for ease of this automation. An

international standard has been created for this purpose: ISO-5211. ISO-5211 compliance

defines a set of standardized mounting dimensions which all manufacturers of

ball valves must employ for ease of mixing and matching actuation packages.

In closing,

we here at ValveMan are more than happy to help you navigate your way through

your applications to ensure the selection of the most efficient and economical solutions(s)

for your valving requirements.