hide

What is a rubber-lined diaphragm valve?

Components of the rubber-lined diaphragm valve

Stem

Compressor

Bonnet

Actuator

Position indicators

Connection

How a rubber-lined diaphragm valve work

Types of actuators used in rubber lined diaphragm valves

Manual actuators

Electric actuators

Pneumatic actuators

Hydraulic actuators

Types of rubber lined diaphragm valves

Weir type rubber-lined diaphragm valve

Straight-way rubber-lined diaphragm valve

Sanitary rubber lined diaphragm valves

Biotech rubber lined diaphragm valves

Hygienic rubber-lined diaphragm valve

Applications of a rubber-lined diaphragm valve

Advantages of rubber lined diaphragm valves

Disadvantages rubber lined diaphragm valves

Troubleshooting rubber lined diaphragm valves

No fluid flow or flow rate very low

Broken flange

Leakage between counter flanges and body valve

Valve is difficult to operate

Seat leakage while the valve is closed

Summary:

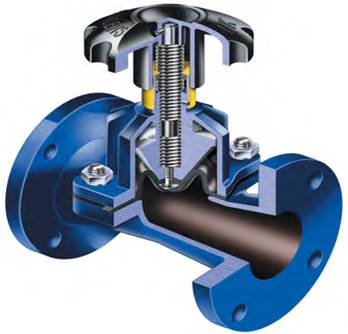

What is a rubber-lined diaphragm valve?

A rubber-lined diaphragm valve is a valve that has its diaphragm lined with a rubber material. This type of valve is used in many applications such as sewage treatment, paper processing, mining minerals, power generation stations, steelworks, and chemical industries. The rubber-lined diaphragm valve has a body made of metal or plastic but a hard and thick rubber lining is used to line the diaphragm. This makes the diaphragm and the whole rubber-lined diaphragm valve safe when handling abrasive and corrosive media. As such, the whole wetted component is protected by the rubber lining preventing hydro abrasion. Rubber-lined diaphragm valve manufacturers make the valves in a wide range of materials to help deliver the full potential of an effective and versatile valve to control fluid flow. With combinations of strong metallic material and hard rubber lining, these rubber-lined diaphragm valves can resist corrosion and abrasion. Rubber-lined diaphragm valve manufacturers make the valves with two or more ports and a saddle or weir. The weir is the part where the diaphragm of the valve seats.

Figure: Rubber-lined diaphragm valve.

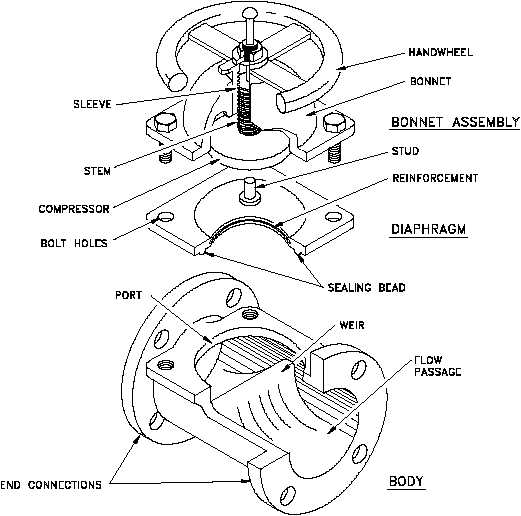

Components of the rubber-lined diaphragm valve

Figure: Components of the rubber-lined diaphragm valve.

Stem

A rubber-lined diaphragm valve has an indicating or non-indicating valve stem. A non-indicating stem is the one in which a handwheel is used to rotate bushes on the stem to engage threads. Such engagement is used to move the compressor mounted to the stem upwards and downwards and which further connects the compressor and the diaphragm. A non-indicating stem employs seal bushes with sealed bonnets. An indicating stem is designed similar to the non-indicating stem but its stem is stretched longer upwards via the handwheel. The indicating body employs a bonnet sealing and sealed bushing.

Compressor

This is the most important component of a rubber-lined diaphragm valve. It is used to move the diaphragm accordingly. The compressor has one end connected to the stem and the other end connected with the diaphragm. When the handwheel is turned it moves the stem upwards or downwards. This helps to transmit the kinetic energy to the compressor. When the compressor receives this energy, it gets the force to move the diaphragm either up or down as it may be needed by the operator thus controlling fluid flow.

Bonnet

This component is used as the housing on top of the rubber-lined diaphragm valve. It contains non-wetted components of the valve like stem, compressor, and handwheel. The bonnet is connected to the valve body using screws. A lever is used to operate the bonnet of the valve. For large valves, it is recommended to use a bonnet that would be vacuum-tight.

Actuator

The actuator is component is a rubber-lined diaphragm valve that is used for operating the stem to close or open the valve disc to control fluid flow. There are different types of actuators used to control fluid flow in valves. The type of actuator used depends on application requirements such as torque, automation, and speed.

Position indicators

These are visual guides used in rubber-lined diaphragm valves to help in identifying position of the valve that is if it is open or closed. Position indicators could be switch, light, or stem. Also, these indicators are installed on valves to show flow direction.

Connection

Rubber-lined diaphragm valve can be connected in various methods. Such methods are:

Compression fittings. These are fittings that can seal piping system connections without welding or threading. The sealing arises when a nut is tightened and a washer is compressed on the second pipe to create a tight seal.

Threaded connection. These are connections that use threads whereby the end of a threaded valve has outer or inner threads that help pipes to screw into or over the valve end. This type of connection is one of the most common and simplest designs of a rubber-lined diaphragm valve.

Metal surface seal. This is a connection that uses a metal gasket between fitting sections. The metallic gasket creates a face seal on both ends of the fittings.

Butt welding. This connection is used to fix butt joints. The joint is fixed between two bars, sections, or plates. This helps to connect the valve and pipe without interlocking.

Socket soldering/welding. This is a connection between parts made by the use of soldering linking pipe and valve.

Clamp flange. This connection is made of a spring flange that is wrapped on a piping system.

Tube fitting. This connection links the pipeline to the rubber-lined diaphragm valve.

Bolt flange. This is a connection used at the valve inlet or outlet.

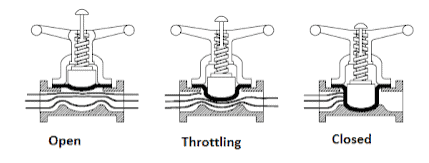

How a rubber-lined diaphragm valve work

A rubber-lined diaphragm valve operates by moving its stem up or down to open or close respectively. When the stem moves upward it moves together with the compressor. The compressor is connected to the diaphragm so they move up together at the same time. The diaphragm is the part that can allow fluid flow to stop or to move. So when the diaphragm moves upwards it allows fluid to flow. To stop or reduce fluid flow, the stem moves down. As such, the compressor and diaphragm move downwards simultaneously making the diaphragm close or reduce the flow.

Figure: Working of a rubber-lined diaphragm valve.

Types of actuators used in rubber lined diaphragm valves

Manual actuators

These are actuators that use a manual mechanism like a handwheel so that the valve operator can apply torque on them to open/close the valve. The torque is necessary as it is used to turn the threaded stem and thus move the stem linearly forcing the diaphragm to alter the fluid flow rate. The problem with manual actuators is that they work at a slow speed and also need more turning effort to close or open the rubber-lined diaphragm valve. To amplify torque in a rubber-lined diaphragm valve manufacturers may decide to use gearheads that can enhance closing or opening speed. These actuators can also have position indicators, stroke adjustment, and electric feedback switches to make use of valves better.

Electric actuators

These are actuators that use a motor to modify the flow rate of the fluid. The power to close or open the valve comes from an electric motor. The motor speed is very high and thus a gear train is used to reduce the speed from the motor and thus increase the torque. In mechanical power transmissions systems when the speed is reduced the torque increases proportionately. The electrical actuators are reversible that is they can open and close a rubber-lined diaphragm valve.

Pneumatic actuators

These are actuators that use air pressure to enhance the closing or opening of valves. The air pressure used moves a piston in the rubber-lined diaphragm valve. The piston rod connects to a compressor. Air pressure is transmitted on either side of the piston chamber. Supplying air pressure on the upper piston chamber makes the piston rod move downwards lowering the flow rate or closing the valve. When the air pressure is transmitted into the lower piston chamber, the piston rod moves upwards increasing the flow rate. Air leakage in the piston and piston rod is protected by the use of O-rings ensuring no air leaks across the chambers.

Hydraulic actuators

These are actuators that use hydraulic fluids to exert the force needed to open or close rubber-lined diaphragm valves. Such hydraulic fluids include water, oil among others. Hydraulic actuators are commonly used in low-speed applications.

Types of rubber lined diaphragm valves

Weir type rubber-lined diaphragm valve

This is a type of rubber-lined diaphragm valve which has been found suitable for leak-free and small flow controls. This valve employs an inclined body design to provide self-draining which can take place in both directions of the weir-type rubber lined diaphragm valve. Despite this valve having been used in many applications, it cannot be used to control fluid flow in some cases. This valve is best suited to control flow in liquids and gases. These valves are suited for clean homogenous fluids as very viscous fluid tend to accumulate on the weir. These valves would work best in water, gas, food, chemicals, and corrosive applications.

Straight-way rubber-lined diaphragm valve

This is a type of rubber-lined diaphragm valve which has a complete straight flow path without the saddle. The rubber-lined diaphragm valves close the fluid flow by making contact with the bottom of the valve. With the diaphragm component being flexible, this valve can last for short periods as well as needing repairs and replacement frequently. Unlike the weir-type valves, these valves can work on viscous fluids and water sludge.

Sanitary rubber lined diaphragm valves

These are rubber-lined diaphragm valves which are mostly used where pure and clean fluid is needed like making wine, beverages, pharmaceutical, dairy, and food processing. This type of valve produces an aseptic area for fluid flow free from fungi, bacteria, and viruses.

Biotech rubber lined diaphragm valves

These valves are manufactured to handle fluid that may contain cells, germs, and similar biological matter. Biotech rubber-lined diaphragm valves are used in piping systems that have bioreactors, chromatography skids, filtration, freeze-thaw, and fermenters. These valves have been used in biotechnology industries such as medicine, pharmaceutical, agriculture, and food science.

Hygienic rubber-lined diaphragm valve

These are rubber lined diaphragm valves meant for use in applications where the fluid flow can stagnate. They are also used to handle food and beverages which need to be free from germs for human consumption or which can make damage food quality.

Applications of a rubber-lined diaphragm valve

- Used in chemical processing.

- Power generation plants.

- It is used in mining and mineral processing.

- Steel production factories.

- They are used in electroplating sites.

- This valve is used in food and beverages processing.

- Textile and leather piping systems.

- It is used in the paints and coating industry.

- Pharmaceutical manufacturing plants.

- Paper and pulp manufacturing plants.

- Control flow in semiconductor and electronics manufacturing.

- Enhance control of flow in sugar production.

Advantages of rubber lined diaphragm valves

- Can be used for on-off and throttling applications.

- This valve is made with many linings that help to guarantee corrosion resistance.

- Guarantee bubble-tight service.

- This valve is free from stem leakages.

- Rubber-lined diaphragm valve manufacturers design the valves ready for slurries and viscous fluids.

- Suitable for controlling hazardous fluids.

Disadvantages rubber lined diaphragm valves

- Used in applications that need moderate pressure and temperatures.

- These valves have weirs that can limit full pipeline drainage.

Troubleshooting rubber lined diaphragm valves

No fluid flow or flow rate very low

- The rubber-lined diaphragm valve is partially or closed. Check valve position.

- Valve packings or protections are still in position. Remove these protections.

- Clogged pipe or strainer system. Clean the system.

Broken flange

- Assembly bolts have low torque, misaligned counter flanges, or they have too much gap. This may need a rubber-lined diaphragm valve to be replaced and installed according to the manufacturer’s manual.

Leakage between counter flanges and body valve

- Counter flanges not fully tightened, valve not well aligned or centered. Check the assembly and fully tightened it. If necessary dismount and mount it again properly.

Valve is difficult to operate

- Jammed or damaged bonnet/stem. Check the bonnet/stem and grease or clean as necessary.

- High pressure. Verify working conditions. Large-sized rubber-lined diaphragm valves need proportionately high torque to operate under pressure.

- Handwheel rotated in the wrong direction. Check the direction of rotation. Note clockwise direction means you are closing the valve.

- Impurities between the body and the valve. Close and open the valve under pressure to clean the trapped dirt. If necessary replace or repair the valve.

- Valve is not in the correct position to apply force. Place the valve in the correct position to make it easy to apply force to close or open.

Seat leakage while the valve is closed

- Damaged diaphragm. Replace diaphragm.

- Damaged body sealing surface. Replace body.

- Impurities between body and diaphragm. Close and open your rubber-lined diaphragm valve under pressure to clean the dirt.

Summary:

Rubber-lined diaphragm valves are types of diaphragm valves that have the diaphragm lined with thick and strong rubber. These valves employ a flexible diaphragm that is used to control the fluid flow. The fluid control is done by moving down or up to decrease or increase fluid flow rate respectively. Rubber-lined diaphragm valves have several components among them stem, valve body, compressor, diaphragm, actuator, position indicators, and connections. Each of these components works together to enhance the full functionality of the valve. Failure of one component affects the other components and may end up destroying the whole rubber-lined diaphragm valve.

Rubber-lined diaphragm valves are of several types. These types depend on mostly design and specific use. Some of the types of rubber-lined diaphragm valves are weir type rubber-lined diaphragm, strait-way rubber-lined diaphragm valve, sanitary rubber-lined diaphragm valve, hygienic rubber-lined diaphragm valve among others. The many types of rubber-lined diaphragm valves lead to many applications of these valves such as pharmaceuticals, food and beverage, steel production, mining and mineral processing, chemical processing, power plant industries among others. The material used to make the diaphragm determines the pressure and temperature rating of the rubber-lined diaphragm valve. In this type of valve, the bonnet, and valve body need to be made of strong and rigid material to ensure that the internal components are protected.