What is a Rising Stem Gate Valve (OS&Y Gate Valve)?

Rising Stem Gate Valve is a type of gate valve which is able to follow the opening/closing position by moving the stem up & down movement, is able to follow electronically the movement by adding a monitoring key, and a fully open position does not disrupt the flow. Rising Stem Gate Valve generates low head loss according to butterfly valves.

The outside screw stem rising through hand wheel type gate valve has extensive applications. Rising stem gate valves can be used in high-pressure ratings up to Class 2500 or up to 420 bar, while non rising stem gate valves are normally used for middle-pressure ratings.

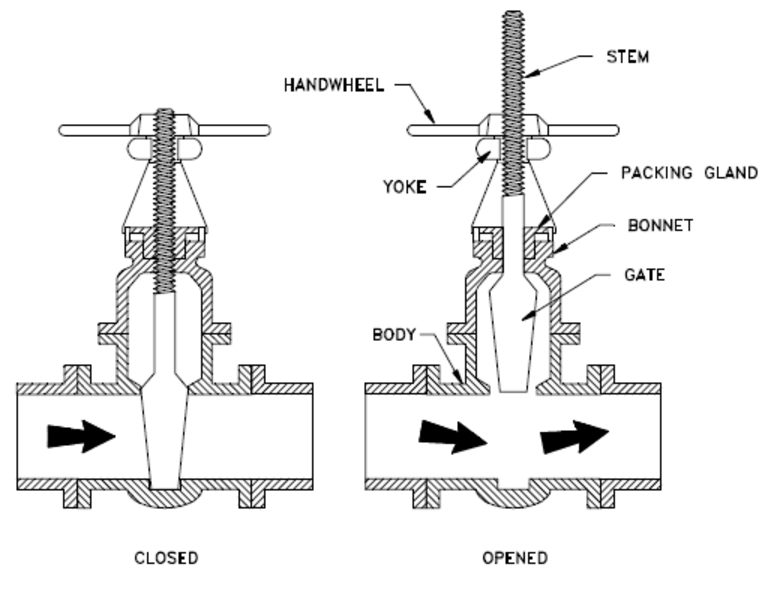

In this way, you can visually keep track of how far the valve is open. With a rising stem gate valve, it is easy to tell if the valve is open or closed by looking at the amount of stem that is exposed. If the handle is flush with the pipe (no exposed stem), the valve is closed. If a lot of stems is exposed, the valve is open.

How does a Rising Stem Gate Valve (OS&Y Gate Valve) work?

Rising stem gate valves dopts the structure that the nut of the valve stem is on the valve bonnet or the valve yoke. When the gate is opened and closed, the nut of the valve stem is made to rotate to rise the valve stem. Since this kind of structure is beneficial to the lubrication of the valve stem and makes the opening and closing process can be seen.

The advantages and disadvantages of Rising Stem Gate Valve:

- Easy to open and close.

- Small fluid resistance, sealing surface by medium erosion and erosion.

- Medium flow is not restricted, with no turbulence, and no pressure reduction.

- The sealing surface is easy to be eroded and scraped, and difficult to maintain.

- A larger structure requires more space and long-time opening.

What is a Non Rising Stem Gate Valve?

Non-Rising Stem means outside stem, also referred to as the rotary stem gate valve or blind stem wedge gate valve.

A gate valve with the non rising stem requires an indicator for showing the extent of opening and closing of the valve itself. However, the inside screw non rising stem gate valve has the disadvantage of being easily damaged because the stem thread is unable to be lubricated and is directly corroded by media.

How does a Non Rising Stem Gate Valve work?

In an NRS valve, the stem will turn to open and close the gate, but the stem does not move up or down as it turns. As the stem turns, it moves into or out of the valve, which also moves the gate to open or seal the valve.

The advantages and disadvantages of Non-Rising Stem Gate Valve:

- Advantages: Non-rising stem valves take up less space, ideal for gate valves with limited space. Generally, an open-close indicator should be installed to indicate the degree of open-close.

- Disadvantages: Failure to lubricate stem threads will result in medium erosion and easy damage.

What is the difference between a rising stem gate valve and non rising stem gate valve?

1、The difference in transmission mode

The transmission mode of the Rising stem gate valve is that the handwheel drives the nut to rotate in place, and the valve stem is linearly raised and lowered. Through the threaded transmission of the valve stem and the steering wheel, the valve disc rises and falls to complete the switch; the Non-rising stem gate valve is a hand wheel that drives the valve stem to rotate. The hand wheel and the valve stem are connected together and relatively immovable. There are threads in the gate, and the valve stem rotates at a fixed point to drive the gate to rise and fall.

2、The difference in structure

The structure of the rising stem gate valve is that the stem nut is on the bonnet or bracket. When the gate is opened and closed, the stem nut is rotated to realize the lifting of the stem. The structure of the concealed stem gate valve is that the stem nut is in the valve body and is in direct contact with the medium; when opening and closing the gate, it is realized by rotating the stem.

3、The difference in installation space

The rising stem gate valve requires a larger installation space because of the stem; the height of the Non-rising stem gate valve is small, and it will not take up too much space during installation.

4、The difference in application scope

The structure of the rising stem gate valve is beneficial to the lubrication of the stem, and the degree of opening and closing is obvious; the stem thread of the Non-rising stem gate valve is not only unable to be lubricated but it is directly corroded by the medium and is easily damaged. Therefore, the open stem gate valve is more The Non-rising stem gate valve has a wider range of applications.

Related Tags :

Ten articles before and after

Outside Screw Stem Rising through Handwheel Type Gate Valves – Zeco Valve | Quality valve supplier

Why Sealing Surfaces of Forged Steel Ball Valves Are Damaged? – Zeco Valve | Quality valve supplier

What Are the Needle Valves? – Zeco Valve | Quality valve supplier

What Are the Knife Gate Valves? – Zeco Valve | Quality valve supplier

The working principle, characteristics and structure of gate valves – Zeco Valve | Quality valve supplier

Differences in Applications between Plug Valves and Ball Valves – Zeco Valve | Quality valve supplier

Origin and Development of Plug Valves – Zeco Valve | Quality valve supplier

Identification of Seamless Steel Pipe – Zeco Valve | Quality valve supplier

Will Stainless steel sanitary valves and fittings rust? – Zeco Valve | Quality valve supplier

The Installation Notes of Wafer Check Valve – Zeco Valve | Quality valve supplier