hide

What is a weir diaphragm valve?

How does weir type diaphragm valve work?

Types of Weir type diaphragm valves

Manual weir type diaphragm valves

Electrical weir type diaphragm valve

Pneumatic weir type diaphragm valve

Hydraulic weir type diaphragm valve

Thermal weir type diaphragm valve

Materials of manufacturing of weir type diaphragm valve

Diaphragm

Ethylene propylene diene monomer (EPDM)

Polytetrafluoroethylene (PTFE)

Neoprene

Butyl rubber

Nitrile rubber

Natural rubber

Valve body

Factors considered when selecting a weir type diaphragm valve

Valve flow coefficient

Pressure drop

Rangeability

Valve sizing

Advantages of weir type diaphragm valves

Disadvantages of weir type diaphragm valves

Applications of weir type diaphragm valves

Troubleshooting Weir type diaphragm valves

No flow or not enough flow

Leakage between counter flange and body

Flange broken

Not able to achieve full opening or closing position

Leakage in the seat when the valve is closed

Summary:

What is a weir diaphragm valve?

The Weir type diaphragm valve is a type of valve under diaphragm valves. This is one of the most popular of all diaphragm valves. Weir type diaphragm valve has a raised saddle or lip where the diaphragm part presses to produce sealing action. Due to the raised lip, the level of diaphragm travel reduces from opening fully to a completely closed position. As such, the induced stress on the diaphragm due to closing the valve decreases. The diaphragm is made of strong material making it suitable for high pressure and vacuum applications. Weir type diaphragm valves perform very well in control of fluid flow, throttling, and control of minute flow rates. Weir type diaphragm valves use a two-piece compressor to create a small opening at the valve center. Weir type diaphragm valves are often used to handle homogeneous and clean liquids and gases since contamination and viscous sludge can accumulate on the saddle. These valves can also work on hazardous, abrasive, and corrosive media.

Weir type diaphragm valve

How does weir type diaphragm valve work?

Weir type diaphragm valve has a flexible diaphragm that is connected to the compressor. The compressor is connected to the stem. To increase the flow rate the stem moves upwards. While the stem moves upwards, it moves together with the compressor since they are connected. The compressor is connected to the diaphragm which then makes the diaphragm also move upwards. When the diaphragm moves upwards, the flow of fluid increases. To reduce the flow rate or to completely close the flow, the stem is turned and moved downwards. The stem then transfers the downward motion on the compressor which also presses the diaphragm downwards to either reduce the flow rate or to completely close the fluid flow.

Types of Weir type diaphragm valves

These diaphragms valves can be classified based on the actuator used and application of that. Considering the actuators the types of weir type diaphragm pumps are:

Manual weir type diaphragm valves

These are weir type diaphragm valves with a crank or handwheel used to apply torque. The applied torque is used to rotate the stem and thus move linearly to alter fluid flow. These type of weir type diaphragm valves have a slow control speed. They also need more manual energy to operate. Some gearheads can be installed in these valves to improve the torque and thus increase closing or opening speed. Despite these valves being manual, they can also have other important features such as position indication, stroke adjustment, and switches for electrical feedback to enhance convenient operation.

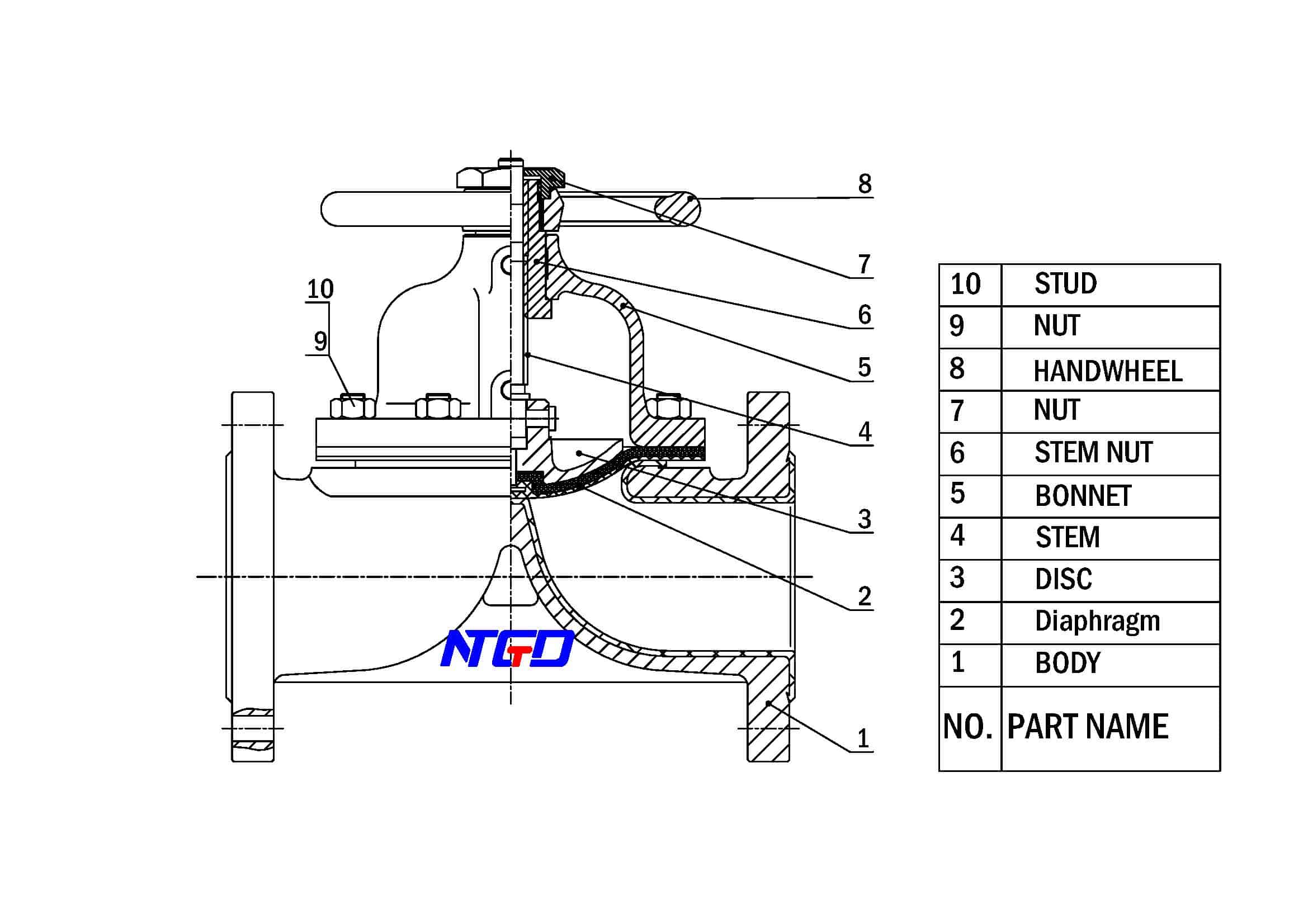

Figure: Manual weir type diaphragm valve.

Electrical weir type diaphragm valve

These are weir type diaphragm valves that have electrical actuators. These valves use an electric motor to modify the flow rate of the fluid. The motor is connected to a gear train to lower the motor speed and increase its torque. By using an electrical actuator these valves can be operated reversibly that is close to the diaphragm and vice versa.

Figure: Electrical weir type diaphragm valve

Pneumatic weir type diaphragm valve

These are weir type diaphragm valves that use air pressure to open or close the fluid flow. They work by moving a piston in a valve bonnet where a piston rod connects to a compressor. Supply of air pressure is done on either side of the piston chamber. Supplying air in the upper piston chamber makes the piston rod move downwards and thus lowering the fluid flow rate or closing the valve as it may be needed. On the other hand, supplying air to the lower chamber makes the piston rod move upwards and thus increases the fluid flow rate. There are O-rings on the piston and piston rod which help to ensure no air leakage across the piston chambers.

Hydraulic weir type diaphragm valve

These are weir type diaphragm valves that use hydraulic fluid like water or oil to close or open valves by exerting large force on the diaphragm. These valves are often used in lower-speed applications.

Thermal weir type diaphragm valve

These are valves that use change in temperature to close or open valves to alter the fluid flow.

Materials of manufacturing of weir type diaphragm valve

Diaphragm

This component of a weir type diaphragm valve is made of elastomeric and flexible material. Such materials have been found to restrict the pressure and temperature rating of the valve as they become weak at high pressures and temperatures. As such, materials for making the diaphragm need to be selected based on expected pressure and temperature, material to be handled, and operation frequency.

Ethylene propylene diene monomer (EPDM)

This is a general-purpose, synthetic elastomer. It is good in corrosion resistance. It can handle alcohols, alkalis, and acids. This material is ozone resistant. However, this material is not compatible with petroleum and oil products. Weir type diaphragm valves made of this material can work between -28 oC to 110 oC. This material is also good where the weir type diaphragm valve will be used in sterilization applications.

Polytetrafluoroethylene (PTFE)

PTFE is a synthetic fluoropolymer. This material has superb chemical and corrosion resistance suitable for handling strong alkalis, acids, and solvents. It is a stiff material which makes it create a large force to operate a valve. A diaphragm made of this material can operate between -184 oC to 1649 oC. PTE material is made strong by reinforcing it with glass fiber which improves its compressive strength, abrasion, and wears resistance as well as pressure rating.

Neoprene

This is a synthetic rubber material often used to make diaphragms. It is known for good abrasion and corrosion resistance. This material can handle fluids with entrained oils, alkalis, acids, explosives, petroleum, and fertilizers. A diaphragm for weir type diaphragm valve made of this material can work in temperatures between -28 oC to 93 oC.

Butyl rubber

This material has low gas and vapor permeability. This makes it suitable for use in gaseous media. Butyl rubber can be used in alkalis and acids and steam sterilization. Diaphragms made of this material can operate between -20 oC and 120 oC.

Nitrile rubber

This material is resistant to abrasion and has high strength. This material can handle gases, fats, fuels, alcohols, oils, and petroleum. However, it is not compatible with ketones, ozone, acetones, and other modified hydrocarbons. Diaphragms made of this material can be used in temperatures between -25 oC and 57 oC.

Natural rubber

This material can handle alkalis and acids and is abrasion-resistant. Diaphragms made of natural rubber are often used in dilute mineral acids, abrasives, and brewing. Such diaphragms can work in temperatures of -40 oC and 57 oC.

Valve body

The bonnet and valve body are made of strong and rigid materials that can protect components of the weir type diaphragm valve. Manufacturing the bonnet from less corrosion-resistant material will be fine because the bonnet will be protected from the wetted part of the valve. Smooth lining the inner diameter of the weir type diaphragm valve will help in preventing gumming and clogging of viscous and sticky fluids. Similar to the diaphragm, the valve body needs to be made of a material that is resistant to corrosion and which can offer sterilization. To enhance a certain degree of sanitary, antimicrobial materials such as bronze and brass can be used. Some commonly used valve body materials for weir type diaphragm valves are cast iron, stainless steel, cast steel, bronze, brass, PVC, ductile iron, CPVC, and U-PVC.

Factors considered when selecting a weir type diaphragm valve

Valve flow coefficient

This is the measure of the valve’s ability to allow fluid to flow through it. It is described as the volume of fluid at 316 oC that can flow through a valve in one minute with a 1 psi pressure drop across the valve. Knowing the valve flow coefficient is very important because it helps to determine the size of the weir type diaphragm valve that can allow fluid at the appropriate flow rate. Increasing the stem travel and valve opening increases the valve flow coefficient.

Pressure drop

This is the drop in pressure from the inlet to the discharge of the valve. When the ratio of pressure drop across the weir type diaphragm valve to the whole system pressure drop is very small, then the flow rate difference would also be very small up to a point when the valve is fully closed. As such, a quick opening or fast-acting weir type diaphragm valve will be of great help.

Rangeability

This is a property of weir type diaphragm valves which are measured in terms of a ratio of maximum to minimum flow rate that can be controlled. The accuracy and size of the actuator, geometries, compressor, valve body, and diaphragm affect the Rangeability. For a higher rangeability, the weir type diaphragm valve would control a wide range of flow rates.

Valve sizing

This consideration is important for weir type diaphragm valves meant for throttling purposes. The needed volume expected to pass through the valve needs to be determined and it is affected by inlet and outlet pressure and temperature, flow rate, fluid viscosity, and specific gravity. When such properties are determined, then the valve pressure drop and capacity of the weir-type diaphragm valve will be determined. There are various methods used to determine the size of the valve. One of the methods is by use of pipe geometry factor.

Advantages of weir type diaphragm valves

- Have many linings that help them to resist chemical damage.

- These valves offer a bubble-tight service.

- These valves are suitable for delivering hazardous and radioactive fluids.

- Weir type diaphragm valves work well in viscous fluids.

- They can be used in on-off and throttling flow applications.

Disadvantages of weir type diaphragm valves

- Have a weir that can cause complete piping drainage.

- If the body of this valve is not made of corrosion-resistant material it will wear rapidly.

- Weir type diaphragm valve may not work well at a very high pressure of more than 200 psi.

- The diaphragm can corrode if used in heavily contaminated throttling services.

Applications of weir type diaphragm valves

- Used in an application with corrosion as they do not give in to corrosion.

- Used to regulate the flow of clean or dirty air or liquids.

- These valves are used in power generation.

- They are used in piping systems of vacuum services.

- Weir type diaphragm valves are used in de-mineralized water piping systems.

- Pharmaceutical production systems.

- They are used in chemical processing.

Troubleshooting Weir type diaphragm valves

No flow or not enough flow

- Valve is partially or fully closed. Check the position of the valve.

- Valve packing/protection not removed; remove them.

- Strainer or pipe system clogged. Check system and clean.

Leakage between counter flange and body

- Counter flange not tight enough or not uniform. Verify assembly and tightening torque, if necessary disassemble and assemble again.

- Damaged flange lining, surface, or gasket. Remove valve from the piping system, clean it and repair damages or replace where necessary.

Flange broken

- Assembly bolts not properly tightened or misaligned counter flanges or large gap. Replace weir type diaphragm valve and install according to the manufacturer’s instructions.

Not able to achieve full opening or closing position

- Wrong rotation of handwheel. Rotate the handwheel in the right direction. The clockwise direction is for closing.

- Bonnet or stem thread damaged or jammed. Inspect and grease or clean parts. If necessary replace the damaged part.

- High pressure. Check working conditions. A large-sized weir type diaphragm valve may need high torque if operated under high pressure.

- Weir type diaphragm valve is in a difficult position for workers to apply force. Keep the valve in a good position to ease valve operation.

- There are impurities trapped between the body and the diaphragm. Open the valve and close it under pressure to clear the dirt. Replace or repair the valve as the need may be.

Leakage in the seat when the valve is closed

- It could be due to a damaged diaphragm. Check the diaphragm and replace it if necessary.

- Damaged body sealing surface. Replace body.

- Impurities clogged between body and diaphragm. Close and open the valve at high pressure to clear dirt clogged. Replace or repair the valve as necessary.

Summary:

Weir type diaphragm valve is one of the types of diaphragm valves. This valve has a raised saddle or lip where the diaphragm presses to create sealing action. The diaphragm of weir type diaphragm valve needs to be made of strong material that can withstand high pressure and vacuum applications. Some of the materials used to make the diaphragm are lined rubber or unlined rubber such as Viton, natural rubber, and fluorine plastic such as PTFE and EPDM among others. These materials offer a wide range of temperatures and are resistant to corrosion.

Weir type diaphragm valve performs well in controlling fluid flow and throttling processes. This valve is often used to control the flow of homogenous and clean fluids as well as gases to avoid the accumulation of viscous sludge and contamination on the saddle. Weir type diaphragm valves can be in radioactive, hazardous, abrasive, and corrosive fluids. Because of the strength of these valves and their ability to work on hazardous and corrosive fluids they are used in many industries such as pharmaceuticals, vacuum service, chemical processing, beverages processing, de-mineralized water, corrosive fluids such as acids and alkalis, and in power generation among others.