Typically, the ball valve has two ways, input, and output. However, for some systems where more than one media is used, a 3 way ball valve may be recommended. The 3-way ball valve has 3 ports (entries) instead of just two. This multiport configuration is able to redirect the fluid from the main valve inlet to two different directions (instead of only one) each served by two separate valve outlets. Other main uses of the 3-way ball valve are that the main flow line is served by two independent and alternative inlets.

The ball of a 3-way ball valve can have an L or a T configuration. Furthermore, these specific kinds of the ball valve are available in a floating or trunnion configuration, with either type of valve end (flanged, socket, or threaded connection) and in a range of plastics, metal, alloy, and stainless steel materials.

The aim of this article is to explain what 3-way ball valves are and how they operate. We’ll also go into the various kinds of 3-way ball valves and their various uses.

hide

What is a 3-Way Ball Valve?

How does a 3-Way Ball Valve work?

3-Way Ball Valve Classification.

L-Type patterns ball,

T-pattern flow balls,

Floating:

Forged 3 way ball valves

Casting:

Actuated:

Features and benefits of 3-Way Ball Valve.

The main features of a three-way Ball Valve are:

The main advantages of a three-way Ball Valve are:

What is the 3-Way ball valve used for?

3-Way Ball Valve selection guide.

3-Way Ball Valve vs 2-Way Ball Valve.

Summary.

What is a 3-Way Ball Valve?

Multi-port valves can be three, four, and five-way ball valves. The most popular multi-port ball valve is a 3-way ball valve. A three-way ball valve has three ports or entry points for gas or fluid flow (media) to move through that are attached to piping or conduit. Depending on the flow path through the valve, these ports are typically defined as one inlet and two outlet ports or one outlet and two inlet ports.

3-way ball valves are common because they are a cost-effective and easy way to control both shutoff and flow paths in a single valve body.

Controlling the flow through a three-way valve is achieved by a variation of how the pipe is lined up, how the valve ball rotates the handle, and how the valve ball flows through the ball.

There are many ways a 3-way ball valve can serve or control the flow depending on different process requirements, one can achieve it using the right valve type and setup. Some of the requirements that a 3-way ball valve can achieve are:

- Restrict the flow completely.

- Mix two different fluids from different sources.

- Flow can be diverted from one destination to another.

- Flow from one inlet can be directed to two different destinations.

- It can block one outlet while allowing flow to continue in another direction.

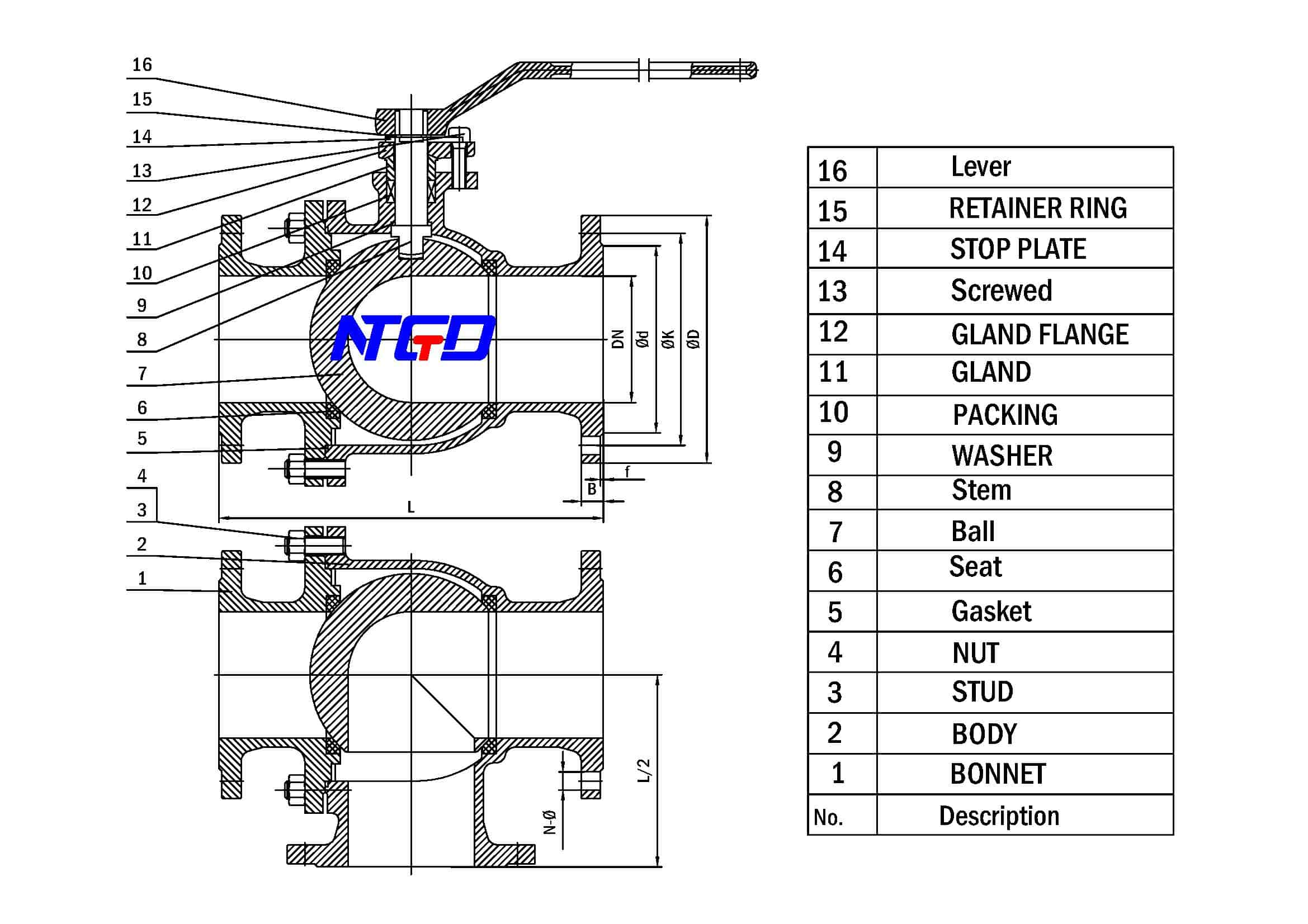

There is a single, but key, internal design distinction that defines what a three-way ball valve will do. This significant design distinction is the flow pattern or outline of the port through the ball within the valve. Most of the three-way ball valves have flow patterned valve balls shaped as either a capital L, which has two flow paths, or capital T, which has 3 flow paths.

How does a 3-Way Ball Valve work?

There are two types of 3-way ball valves, which are a little different from the common ball valve working.

The L-pattern style or diverter valve makes a shift in the flow from one port to the other by rotating the handle or actuator to 90 degrees. Suppose the first position is opened by the bottom port and the left port. A quarter turn in the counter-clockwise direction causes the valve to divert the flow of the media to the right outlet. Another quarter turn in the other direction, allowing a complete rotation of 180 degrees, blocks the passage of media. A 270-turn will also obstruct the media movement. However, having a complete 360-turn enables the valve to return to its original place. In a manner, two of the three ports are available at one time. This makes it possible for the valve to have two shut-off positions and three flow choices.

The T-pattern is called a mixer valve since the media of two inlet flows can be mixed within the valve. It’s leaving the valve on the other end. In a way, all three ports can be opened at one time. The T-pattern ball valve will also act as a diverter so that it can operate in the same manner as the L-type valve. It could be achieved with a quarter-turn of the handle. T-patterns cannot have a bubble-tight shut-off, but they can restrict the flow to two ports or facilitate the passage to all three ports.

As a mixer, the T-pattern ball valve will separate the media into two opposite directions. Its design helps the T-pattern to divide the flow or simply make a straight-through flow pattern, just like the two-way ball valve. The typical port is still open for the vertically mounted T-pattern ball valve. The only way to divert the flow is by turning it a quarter turn. A 180-turn is not going to alter the flow of the media.

3-Way Ball Valve Classification.

L-Type patterns ball,

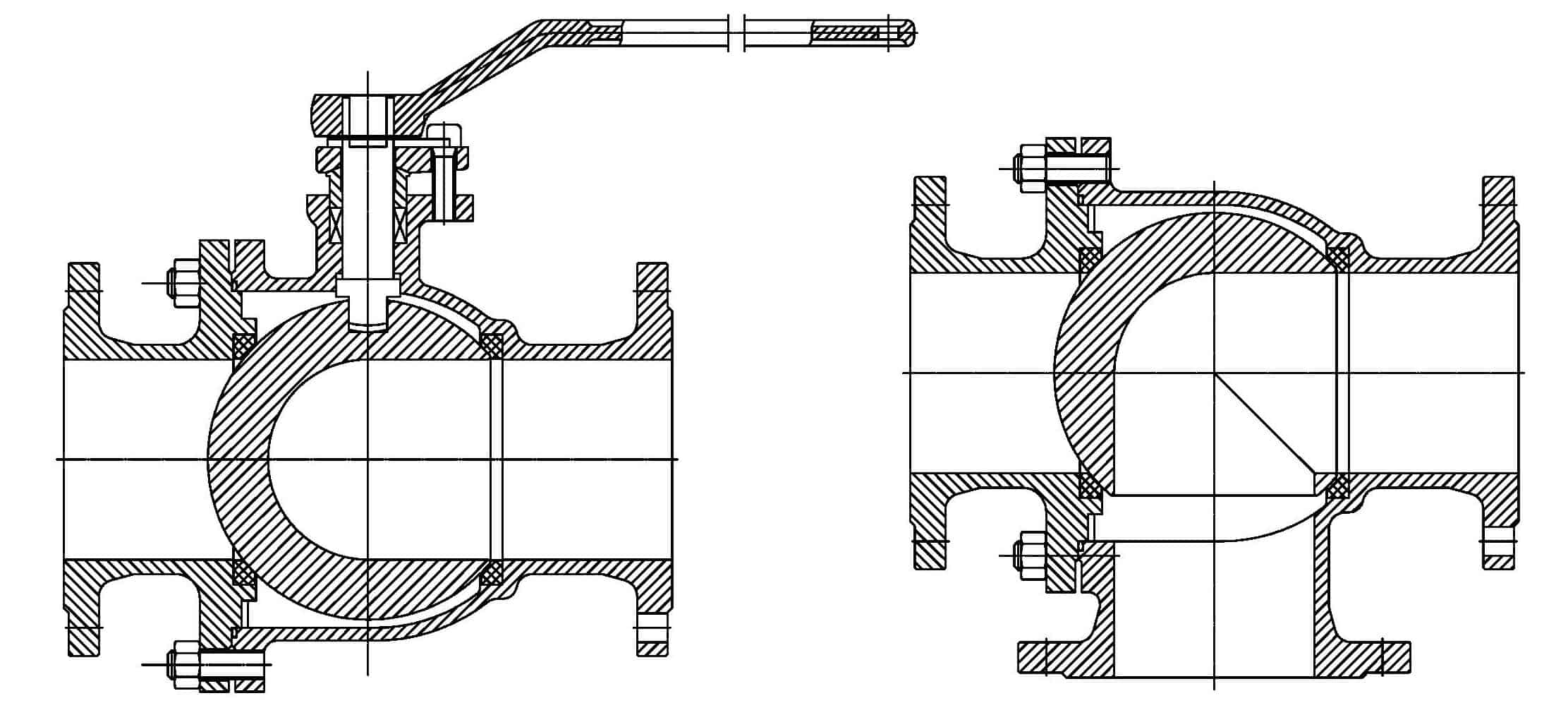

also known as 90-degree balls, are most widely used to facilitate flow from a single common inlet port to one of two separate outlet ports. This is why L-Type pattern flow three-way ball valves are generally referred to as diverter valves.

L Type Three Way Ball Valve

T-pattern flow balls,

also known as 180-degree balls, are commonly used to merge two inlet flows into one common outlet port. The opposite is, also possible depending on the system requirements. T-pattern flow valves are useful for more than just separating or dividing flow. They may also act as L-pattern flow valves, diverting flow from one outlet port to the other. They may include diversion flow, mixing or split flow, and straight through flow based on the permissible range of handle motion.

T Type Three Way Ball Valve

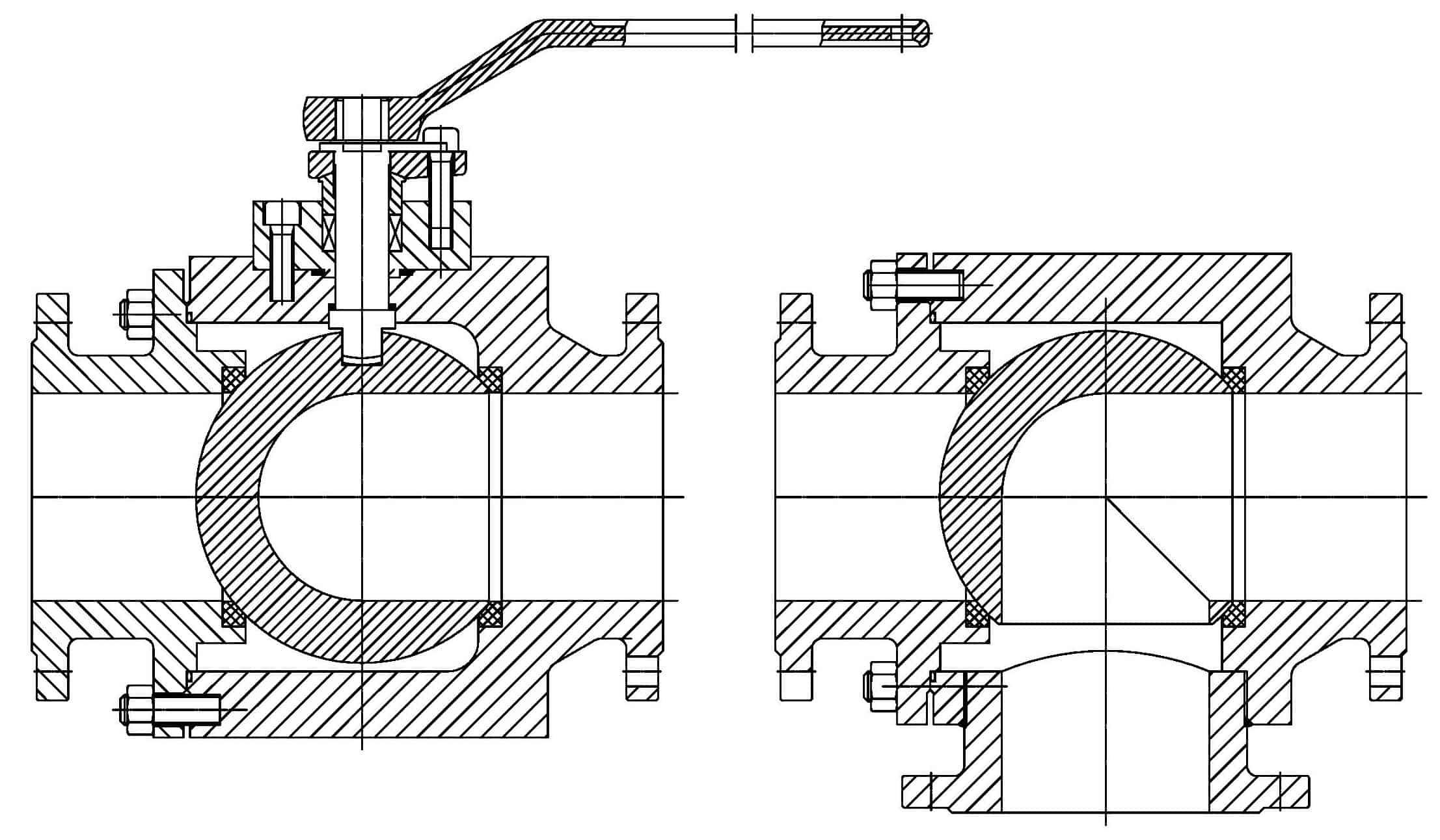

Floating:

The ball is held in place in a floating ball valve by the compression of the two elastomeric seats against the ball. Within the valve body, the ball is free to float. This valve configuration also allows bi-directional shut-off. When the upstream pressure is high, the floating valve is highly difficult to operate.

Forged 3 way ball valves

Forged 3 way ball valves are made by a procedure called forging, which includes shaping metals and alloys when they are solid. Forged valves are known for their strength, making them suitable for high-pressure and high-temperature applications. The grain structure of the metal becomes more refined during the forging process. As a result, effect and overall strength increase. Forging also improves its resilience to typical problems including cracks, shrinkage, and porosity.

Forged body three way ball valve

Casting:

as compared to forging, requires a liquid type of metal to produce valves. These metals are melted poured into moulds of different shapes and sizes. The liquid is broken out of or extracted from the mould until it has cooled and solidified. One of the most important advantages of casting is that it allows for the production of valves with complex shapes, designs, and sizes. When you use a mould to create these instruments, you have more versatility in terms of making various types of valves with more critical parts.

Manual:

Here valves are operated manually with the help of a hand-wheel or a hand lever and used normally to start and stop the flow.

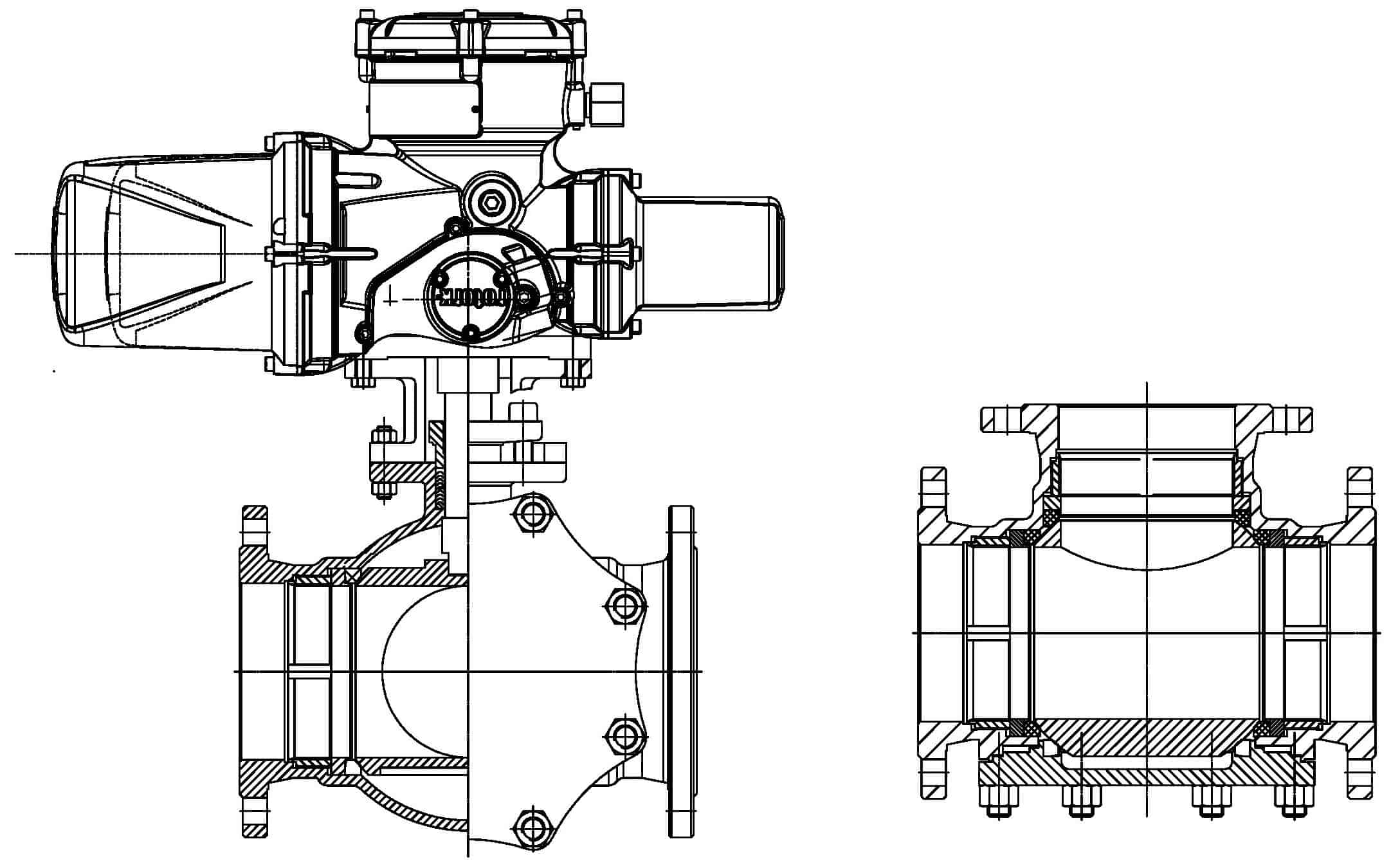

Actuated:

A valve actuator is a mechanical system that controls a valve with the aid of a power source. This source of power may be electrical, pneumatic, or hydraulic.

Features and benefits of 3-Way Ball Valve.

The main features of a three-way Ball Valve are:

- It opens and closes without friction, in turn, less torque is required to turn the valve.

- On-line maintenance of valve adds the advantage of time-saving and cost-effectiveness.

- It features a wedge sealing surface in which the valve uses force provided by the stem, which presses the ball against the seal to provide a positive seal irrespective of any differential pressure condition in the pipeline.

- It is considered to be a self-cleaning valve as when the valve lifts from the seat fluid wash off all the accumulated things and the sealing surface is always clean from debris.

The main advantages of a three-way Ball Valve are:

- It provides a simple structure, compact design, low volume and is less in weight.

- It provides low resistance to fluid passing through the valve.

- The sealing of the valve is good, it is also employed in vacuum systems.

- Maintenance is simple and time-saving.

- It comes in various sizes which increases the range of applications it can be used.

What is the 3-Way ball valve used for?

A three-way multiport ball valve is commonly used as diverting valves, shut-off valves, by-pass valves, selection valves, directional valves with the help of an L-type ball.

A T-type ball valve can be used as sampling valves, mixing valves, by-pass valves, purge valves, uniform flow valves.

3-Way Ball Valve selection guide.

The main consideration while selecting the right valve for your application are:

- Determine the fluid to be used in the system, this is required to choose the right and equivalent valve seal.

- Determine the pressure rating of the system where the valve needs to be fitted.

- Know the temperature to which the system usually works on.

- Check the connection type whether the valve is compatible to be connected to the piping or not.

- The material used for the valve body must be compliant with the existing process lines and appropriate for the process temperature and pressure.

- Determine the operation mechanism of the valve and whether it is feasible for application in the existing system.

3-Way Ball Valve vs 2-Way Ball Valve.

The 3-way valves comprise of the same elements as the 2-way valves. What makes it distinctive from the 2-way valve is the use of an extra port. Like 2-way valves, 3-way valve assemblies may also be operated by pneumatic or electrical actuators.

These valves may be used either to redirect fluid flow or to mix fluids from two inlets to a single outlet. When used as a mixing valve, fluids from inlet ports are mixed within the valve body and then transferred by the outlet port. While a 2-way valve can only be used for on/off applications and sometimes for variable flow system which experience change in Pressure, Temperature, and Flow.

3-way valves are much more cost-effective for diverting and mixing operations than multiple 2-way valves. The ability to blend fluids from more than one inlet makes 3-way valves suitable for heating and cooling different media such as water, oils, and chemicals. These valves are often widely used as bypass valves in both primary and secondary loop applications. Similar to 2-way valves, 3-way valves can also be used in the same process industries described above.

Summary.

Three-way ball valves are classified based on their flow patterns, handle direction, and the range of 90-degree turns the handle can make.

Gas and liquid flow can be redirected, blended, blocked in one direction, or entirely cut off based on how the valve ball is drilled and the piping configuration. Multiport valves minimize space by eliminating the need for an additional tee and a valve. Understanding the fundamental three-way ball valve configuration choices makes it simpler to choose the appropriate three-way valve and prepare its installation.

All you need to know about ball valve

All you need to know about floating ball valve

All you need to know about trunnion ball valve

All you need to know about top entry ball valve

All you need to know about double block and bleed valve