1 1 2 butterfly valve

1 1/2 butterfly valve

3 in butterfly valve

4 butterfly valves

From product design to customer requirements, ZECO Valve Group is composed of valve expert team with profound industry and product knowledge, using the most advanced 3D design software, from concept to detailed design and verification, to production details. The design verification process includes finite element analysis of stress, deflection, thermal effect and flow and computational fluid dynamics simulation. ZECO Valve uses front-end design and development tools to develop and improve product designs to ensure that products consistently meet the highest international standards.

Focusing on safety, low maintenance, long service life and high quality, ZECO valve China designs each product series and optimizes all production details to provide competitive prices. ZECO’s design team can ensure the fastest response to meet the requirements of customers around the world. The r&d team is an important part of the engineering team of ZECO.

The services we provide include technical project management, design and analysis, standard and customized experimental work, performance evaluation, and technical support from project start-up to project completion. Worldwide, ZECO valves are the preferred valve supplier of valve automation solutions for low temperature, low emission, large size and high pressure international standard valves.

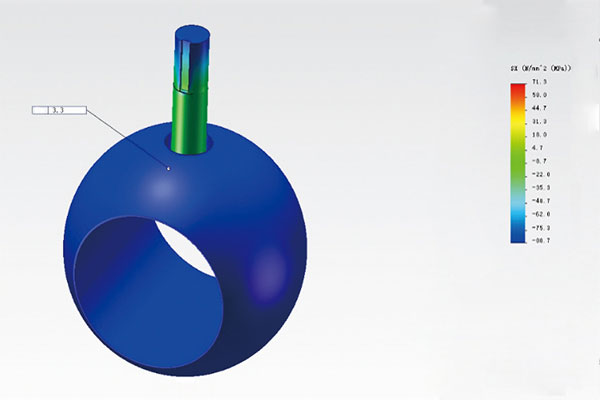

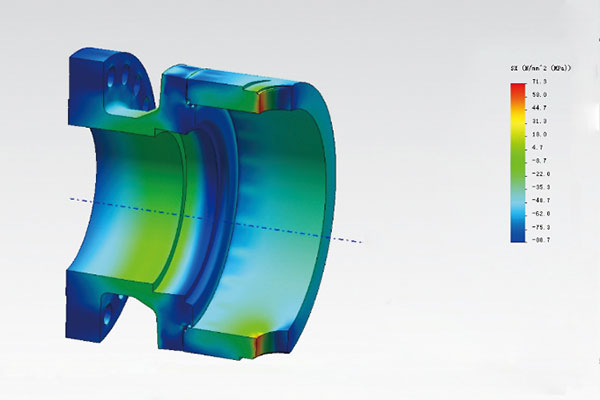

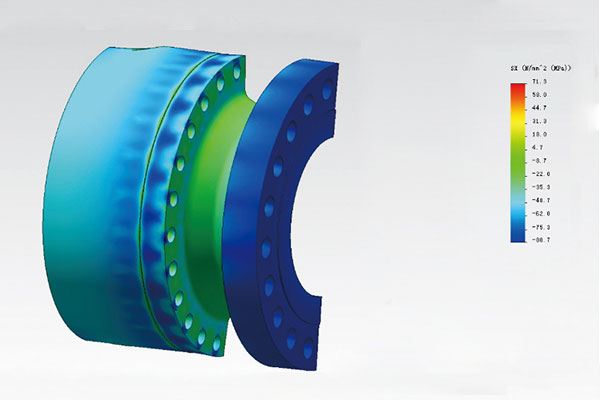

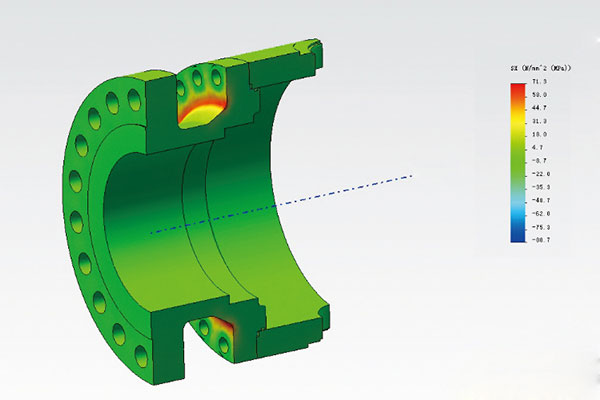

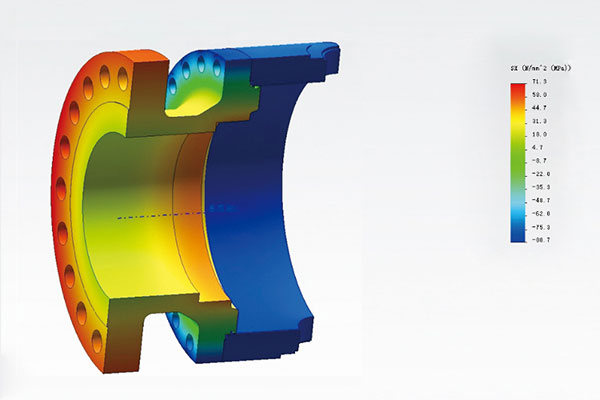

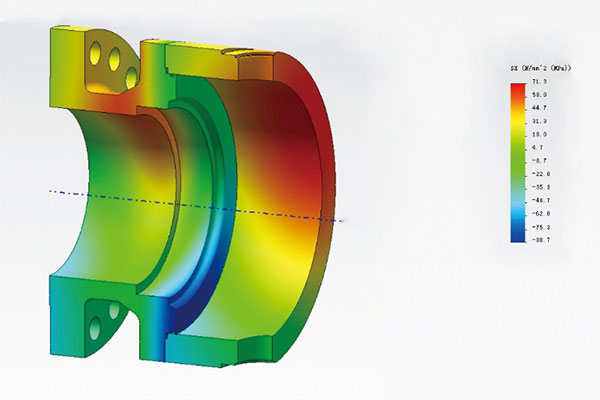

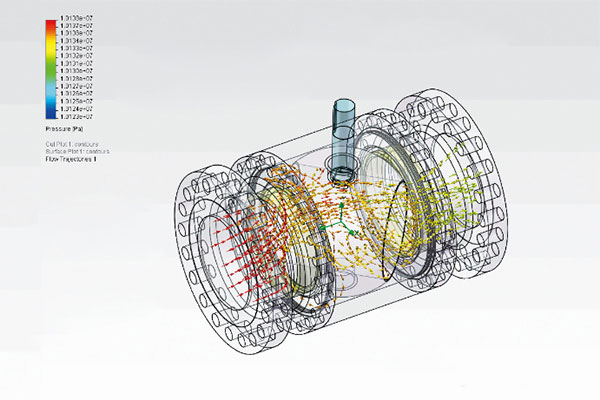

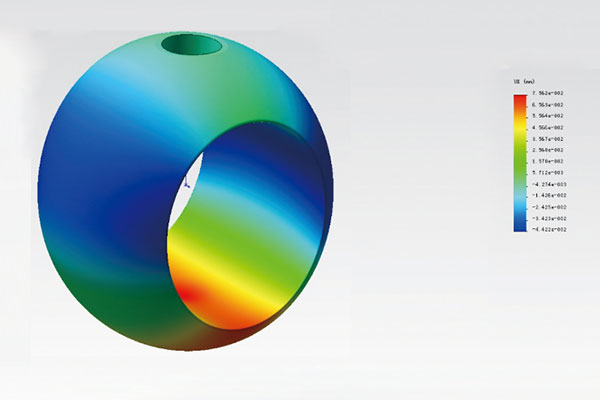

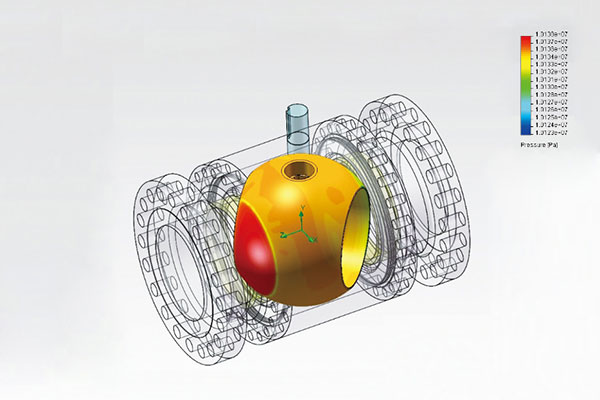

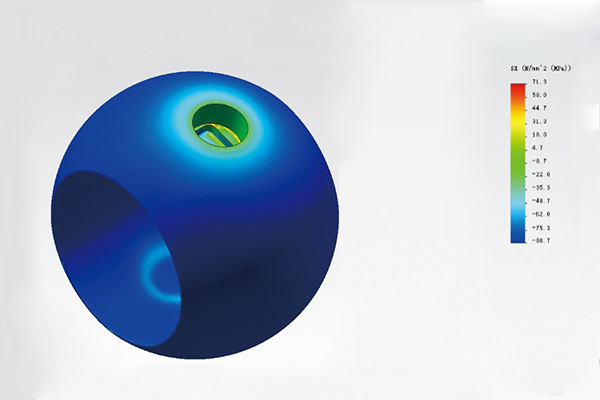

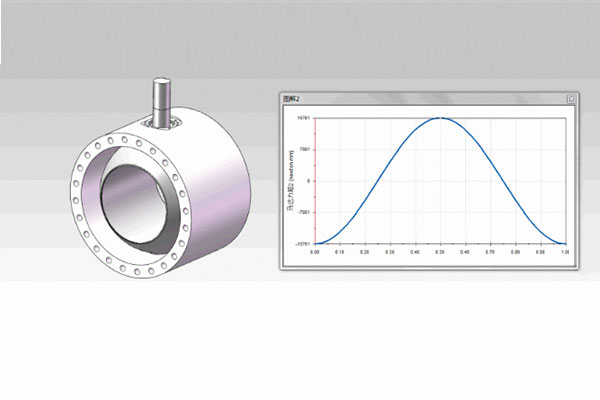

Design and Analysis of Ball Valve:

1、Internal stress distribution of bolted connections under internal pressure

2、Outside stress distribution of bolted connections under internal pressure

3、Radial stress distribution in bolted connection under internal pressure

4、Axial displacement of bolted connection under internal pressure

5、Radial displacement of bolted connection under internal pressure

6、Flow analysis at 45 degrees with ball valve open

7、Radial deformation of the sphere under pressure

8、Pressure distribution on the surface of ball in a flow field

9、Distribution of core stress under torque

10、Dynamic stress analysis of quick opening and closing ball valve stem (<0.5 s)

11、Dynamic stress due to maximum torque