4 ball valves

npt valve

ball valve kitz

cone valves

harrington valves

Table of Contents

- What is a Tunnion Ball Valve?

- Construction of Trunnion Ball Valve

- How does a Trunnion Ball Valve work?

- Types of Trunnion Ball Valves

- Based on Body Configuration

- Based on Bore

- Based on Sealing Material

- Applications of Trunnion Ball Valves

- Characterlistics of Trunnion Mounted Ball Valve

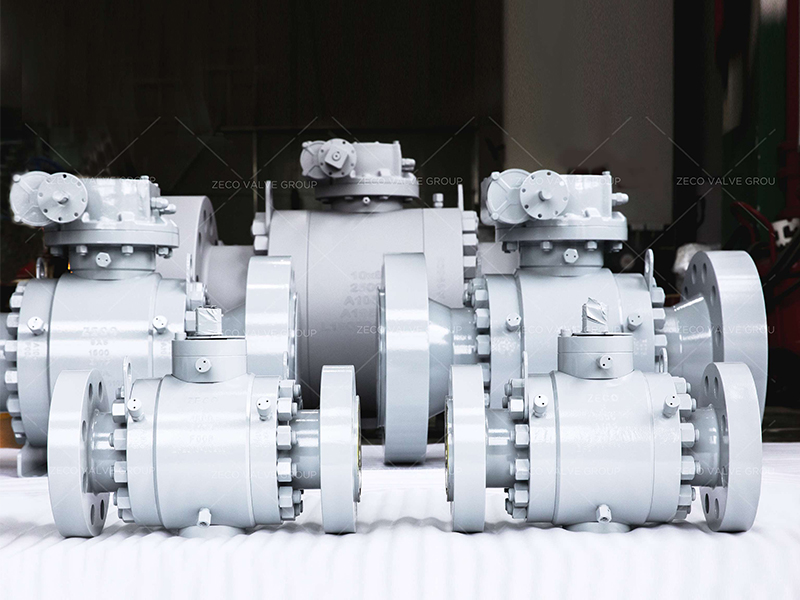

What is a Tunnion Ball Valve?

The trunnion ball valve is an essential device for regulating the flow of fluids- steam, gas, or oil in pipeline. It is quarter-turn designs with a ball capable of rotating 90 degrees on its axis to either block or allow the flow of fluid. These valves have a spherical disk design at the center, which rotates to regulate the start-stop flow cycle. The disk often called the ball comes designed with a small protruding shaft at the top and bottom which are mechanically supported. In this case, flow is controlled by the position of a hole in the center of the ball. For their versatility, Trunnion mounted ball valves are useful in industries where such shut-off operation is required.

The Trunnion ball valves have adequate backing for the ball. The support is in shape similar to a shaft, and it’s called a trunnion. The Trunnion soaks up any additional pressure coming from the flow, thereby lowering the pressure on the valve seat and the ball. Trunnion mounted ball valves find their use in large-scale implementations that require low operating torque.

Construction of Trunnion Ball Valve

Trunnion mounted ball valves have a similar structure as traditional ball valves. The only difference is that trunnion ball valves have additional mechanical anchoring that supports the ball or disk. In this design, the ball is supported from both ends on the x-axis, so that it stays in place and is easy to control. Here is a look at the different parts of a trunnion-mounted ball valve.

- Body

- The body of the valve is the casing that holds and protects the internal parts of a trunnion mounted ball valve. It can be made of carbon steel, stainless steel, low-temperature carbon steel, duplex, super duplex, Inconel, and more depending on the application. While metal seat ball valve and carbon steel ball valve are very suitable for high-temp applications.

- Stem

- The stem of a trunnion mounted ball valve connects the ball to the actuator. It is connected to the ball through welded joints and it controls the movement of the ball. Trunnion ball valves have reinforced anti-blowout stems, that’s why they can handle cryogenic and high-temperatures without sustaining any damage.

- Seats

- The seats of a trunnion-mounted ball valve surround the ball. When the actuator is turned, the seats hold the ball snugly in place, sealing off any access. Trunnion ball valves have spring-loaded seats that move towards the ball as it is held firmly in place.

- Trunnion

- In a trunnion mounted ball valve, there is an additional shaft that holds the ball in place from below. This small shaft is known as a trunnion and it keeps the ball firmly in place. In some ball valves, the trunnion is an extension of the ball while in others it is connected to the ball through welded joints.

- Disk

- The disk in a trunnion mounted ball valve is in the shape of a perforated, solid ball. The ball is connected to the stem on one end and the trunnion on the other. In a trunnion ball valve, the ball or disk is held in place while it rotates. The seats are always in contact with the ball, hence reducing torque.

- Actuator

- The actuator in a trunnion ball valve is used to open or close the valve. There are different kinds of actuators used in ball valves depending upon the application and medium such as air operated ball valves. Bare stem, gear, hand lever, pneumatic actuator, and hydraulic actuator are some common actuators found on the valve. You can also use a gas actuator, gas-over-oil actuator, motor-operated actuator, hydraulic/electric actuator, hydraulic-operated actuator, and more.

How does a Trunnion Ball Valve work?

The trunnion forms the base onto which the ball is mounted. At the top end, the ball is linked to the stem and the stem is connected to an exterior actuator lever. In a flanged trunnion ball valve, there are spring-loaded seats and a polymer ring insert between the trunnion and the ball. The springs put pressure on the ball to keep it in place. Together with the polymer ring, they also reduce friction when the ball is rotating.

To facilitate the flow of media, the ball is made hollow in the middle. It can either be a full bore or a partial bore. A full bore is a ball whose hollow part is the same size as the pipeline it is installed in. Whereas in a partial bore, the diameter of the ball’s hollow part is smaller than the diameter of the pipeline.

When the actuator is turned, the stem connected to it also turns. These actions cause the ball to rotate on the trunnion to an open or closed position. During and after fluid flow, seals in the seats and stem prevent the fluid from leaking out of the pipeline. An adjustable gland packing box also helps the valve take on different capacities of pressure. A typical trunnion ball valve would also have 2 bleeders for purposes of depressurization.

The structure of a trunnion ball valve makes it ideal for application in high pressure and high-temperature fluid management applications.

Types of Trunnion Ball Valves

Based on Body Configuration

- Side Entry Trunnion Ball Valve

- This type of design is also referred to as the split body trunnion mounted ball valve. It assembles its ball from the side.

- Top Entry Trunnion Ball Valve

- This trunnion ball valve is a unique design that assembles the ball from the top.

- Welded body trunnion ball valve

- This design is mainly an application for the transmission of gas in buried pipelines.

Based on Bore

- Full Bore Trunnion Ball Valve

- In the case of full bore trunnion ball valves design, the diameter of the bore aligns with the connected pipeline.

- Reduced Bore Trunnion Ball Valve

- A reduced bore valve is a design that has a bore size lesser than the connected pipeline’s diameter.

Based on Sealing Material

- Soft Seat Trunnion Ball Valve

- Soft seats are typically constructed of thermoplastic substances such as PTFE, DEVLON, PEEK.

- Metal Seat Trunnion Ball Valve

- The main difference between metal seated valves as against the soft seated trunnion ball valves is its ability to survive high temperatures and harsh service conditions.

Applications of Trunnion Ball Valves

Trunnion mounted ball valves are extremely versatile. They are used in many different kinds of industries because of their customizable features. For example, Trunnion Mounted Ball Valve features O-rings and fire-safe stem packaging that prevent leakages. It also comes with stainless steel sealant injection fittings for emergency stem or seat sealing. Trunnion mounted ball valves are used widely in chemical, petrochemical, oil and gas, LNG, hydrocarbon industries.

They are also used for many different kinds of applications including skids like turbine, compressor, generator, and separator, field gas, polymer, LNG, crude oil, and industrial gas processing plants, tank farms, automated process applications, hydrocarbon processing, and oil refinery feedstock lines. Trunnion mounted ball valves are suitable for both large scale high-pressure applications and compact, low-temperature situations.

Characterlistics of Trunnion Mounted Ball Valve

Although there are many types of trunnion mounted ball valves produced by trunnion ball valve manufacturers, they all have the following characteristics:

- Its operation is labor-saving: the ball is supported by upper and lower bearings, which reduces friction. It eliminates the excessive torque caused by the enormous sealing load formed by the sphere and seal seat driven by the inlet pressure.

- Reliable sealing performance: PTFE unisexual material seals are embedded in stainless steel seats with springs at the end of the metal seats to ensure sufficient preload of the seals. When the sealing surface of trunnion type ball valve is worn out during use, the valve will continue to ensure good sealing performance under the action of spring.

- Fire-proof structure: In order to prevent the PTFE sealing ring from burning down due to sudden heat or fire, and to increase the fire potential, a fire-proof sealing ring is set between the sphere and the valve seat. When the sealing ring is burned down, under the action of spring force, the seat sealing ring is quickly pushed onto the sphere to form a metal and metal seal. It has a certain degree of sealing effect. The refractory test meets the requirements of APl6FA and APl607 standards.

- Automatic pressure relief function: When the medium pressure in the stagnant chamber of the trunnion mounted ball valve increases abnormally beyond the pre-force of the spring, the seat retreats away from the ball to achieve the effect of automatic pressure relief, and the seat is automatically restored after pressure relief.

- Drainage pipeline: Both upper and lower parts of the valve body are equipped with discharge L, which can check whether the valve seat leaks or not. In work, when the valve is fully open or closed, the pressure in the middle chamber can be discharged and the filler can be replaced directly. The residue in the middle chamber can be discharged to reduce the medium pollution to the trunnion mounted ball valves.

ZECO Valve is one of the most professional trunnion mounted ball valve suppliers. For more information of product features, please visit our website at http://www.zecovalve.com/.

Related Tags :

ZECO Valve

Gate Valve vs Ball Valve

NBR Butterfly Valve

What is an Axial Check Valve

Gate Valve Repair

What is a Globe Valve?

Manual Operate Gate Valve Manufacturer

Difference Between Gate Valve And Butterfly Valve

What are Globe Valves?