air valve ball

ball valve suppliers

ball valve supply

brass ball valve 1/4

cpvc ball valve 3 4

Table of Contents

- What is knife gate valve?

- Where are knife gate valves used?

- What is the difference between knife gate valves and gate valves?

- Features of knife gate valve

- What is Penstock valve?

What is knife gate valve?

Knife gate valves are designed mainly for on-off and isolation services in systems with high content of suspended solids. Knife gate valves are especially beneficial for handling slurry in addition to viscous, corrosive and abrasive media. The valves have a minimised pressure drop in fully open position, they are easy to actuate, they have a relatively low weight and are cost-effective.

Where are knife gate valves used?

Knife gate valves are designed to work in some of the harshest environments, typically having a sharpened blade to cut through heavy liquids.

They are especially useful in wastewater applications where corrosion is an important issue. So, in addition to the valve design optimised for slurry media, it is beneficial to have a knife made of acid-proof stainless steel as this makes it less susceptible to damages caused by corrosion and as a consequence it needs less frequent maintenance or even replacement.

Knife gate valves should only be used for applications requiring a completely open or completely closed position and should not be used to regulate flow unless they are designed for it. Whenever fluid is forced against a partially closed gate, there will be a vibration, gradually eroding the disc and seat. In addition, the knife gate valves are designed to slowly open and close to safeguard against the impacts of water hammer.

What is the difference between knife gate valves and gate valves?

Both the wedge type gate valves and the knife gate valves are primarily designed for on-off services where the valve is completely opened or completely closed. It is not recommended to use neither of these to regulate flow because when fluid pushes against a partially closed gate, vibration occurs, and cavitation will eventually damage the seat and the body. Also, both valve types are designed to open and close slowly in order to reduce the risk of water hammer.

Features of knife gate valve

- Protective stem cover is standard increasing cycle life in hazardous environments

- Unique J-ring steel-reinforced, elastomer sleeve design provides energized, zero leakage shutoff in both directions. Retaining rings included as standard throughout the entire size range

- In the open position, the energized sleeves shield all metal components from direct contact with the flowing process media

- Robust gate designed for high pressure slurry applications and available in a wide range of corrosion resistant alloys

- Unrestricted flow path with minimal pressure drop achieved through full port valve design for extended sleeve life

- Designed with ample clearance for push-through allowing complete gate closure

- Flanged two-piece bolted body allows for easy maintenance and is drilled and tapped to ASME CL150 flange patterns as standard. Other drilling options available upon request

- Bottom flush plate with tapped ports offered as an option, allowing for safe discharge of media and easy flush water connection

What is Penstock valve?

Penstocks are mainly used for water treatment, power stations, hydraulic installations, purifying systems, etc… Zeco penstocks are provided with a square, rectangular or round port and are manufactured according to customer and site specifications.

The standard design consists of a frame and a sliding gate and depending on the pressure head, the penstock is also provided with polyurethane slides that guide the gate in its course. The uni-directional or bi-directional tightness is achieved by the contact between a soft seal joint and a stainless steel surface. Standard models are manufactured in stainless steel, providing a high corrosion resistance suitable for a wide range of applications. Materials such as Duplex or Superduplex can be supplied on request.

Rectangular Port/Square Slide Gate Valve/ Penstock usually is mainly used for water supply and drainage, chemical flood control, water conservancy and other hydraulic structures, outlets, working channels switching or cutting off water flow.

Depends on amount method can be Canal/Channel gate valve, Wall- attached Slide gate valve/Wall -Mounted Penstock

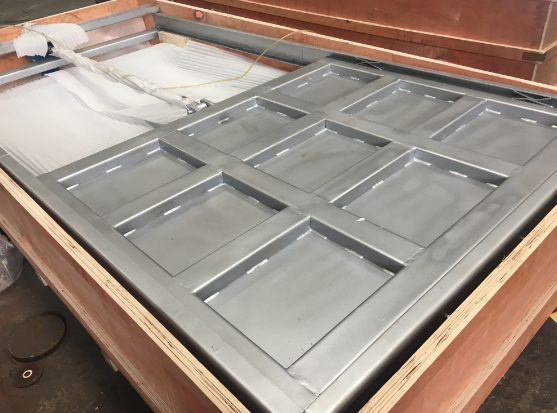

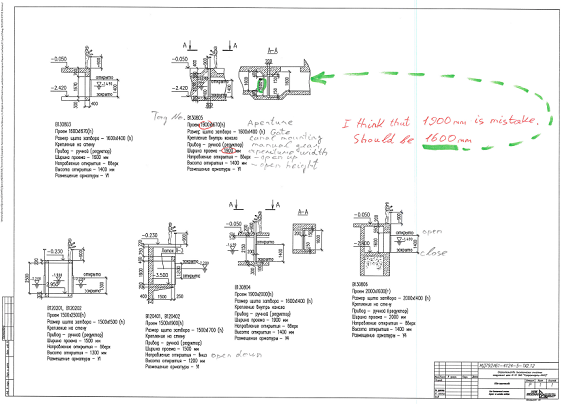

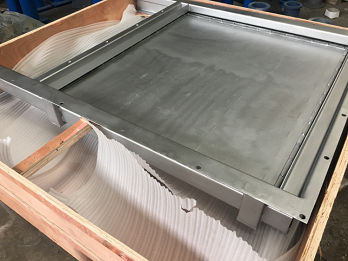

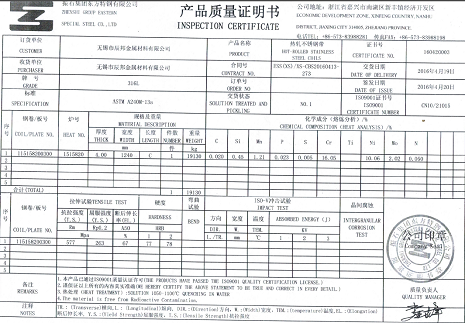

Rectangular knife gate /Stainless steel Penstock Used for Russia Oil Refinery Phase I

The order include: chanel mounting gate valve, and Wall mounted Down-open sluice gate valve, Down-close Sluice gate valve

Material: Square:304,316 /316L Disc/Gate:304,316/316L , Stem:316 Seat:EPDM

Seal: 3 side seal uni-directional, 4 sides Bi-directional Seal, 4 sides Uni-directional Seal

Size: DN1500*DN1500 DN1000*DN1000 DN1600*1400 DN2000*DN1400 DN1600*DN1400 DN2400*DN1800

Operation: Manual/Pneumatic, Include Remote control 6.6 meter (Long Stem extension Sluice gate valve)

Max Water Head: Uni-direction 8 meter, 4 meter (Prefered direction), Bi-direction 8 meter

reference Standard : AWWA .501 ,CJ/T 3006

Attachment: with Rubber Spare parts, Mounting 304/316 M19*140 M16*120 Expansion Bolt, Operation/Mounting manual

Qty: 15piece

Package: Export Seaworthy Wooden Case

Deliver: By Air/Train

Similar Supplier: Orbinox, Vortex,CMO, AWMA

ZECO Valve Offer kinds of Standard and Custom tailer made Slide gate valves, Penstock valveWith Exteme Short Delivery time

Related Tags :

ZECO Valve

Gate Valve vs Ball Valve

NBR Butterfly Valve

What is an Axial Check Valve

Gate Valve Repair

What is a Globe Valve?

Manual Operate Gate Valve Manufacturer

What are Globe Valves?

Difference Between Gate Valve And Butterfly Valve

Ten articles before and after

Oilfield services firm Weatherford to file for Chapter 11 bankruptcy

Concentric Butterfly Valve Stock/fast delivery Available-Europe Wareshouse

API 6D Stainless steel/Carbon steel Spring Return Deadman Lever Operated Ball Valve

Promoting Green Casting is the Development Trend of Valve Casting Industry in the Future

New excellent valve product – Semi-ball valve

Extension long stem concentric butterfly valve for Germany plant

Oxygen globe valve: copper alloy globe valve

The market competitiveness of cast iron valves is further reduced?

Technical Specifications for Valve Selection and Configuration

Is Valve quality the reason of China chemical EXPLOSION: Yancheng chemical factory In March 21th