bristan shower valve replacement

caravan shower valve

concealed shower diverter valve

What is a duplex valve?

A duplex valve is a valve that is made of the duplex steel. Duplex steel is a type of stainless steel material with two phases of the metallurgical structure: the austenite and the ferrite, in almost equal proportions. Duplex material provides better corrosion resistance and higher strength than standard steel. Duplex valves are thus very strong relative to other steel valves. Considering the high melting point of the duplex, this valve has a high thermal resistance and is thus suitable for high-temperature applications such as boilers and power plants. Duplex valve manufacturers recommend this valve for use in high pressure applications due to its high strength. It operates by allowing, throttling, and stopping fluid flow. A disc or ball component is used to control the fluid flow. The valve operates as manual automatic. The manual valve has a handle or handwheel while the automatic one uses pneumatic or electric actuator.

Types of duplex valves

Duplex globe valves

This is the best valve for throttling applications. The basic design of this valve has a spherically shaped body. A disc installed inside the valve helps to stop and regulate fluid flow. The valve body consists of two halves that are separated by an internal baffle. This design makes cleaning and repair a challenge. The design also leads to a lot of pressure loss compared to all other valves. Duplex valve manufacturers have various types of this valve: the Z-pattern type, oblique pattern, and angle pattern.

Figure: Duplex globe valve.

How does the duplex globe valve work?

A duplex globe valve uses a handwheel or actuator to move the valve stem up or down to open or close flow respectively. The working principle remains the same whether the valve uses a handwheel, electric or pneumatic actuator. When the valve operator rotates the handwheel in counterclockwise directions, the valve stem rotates as it moves up with the valve disc. Moving the disc up leaves space for the fluid to flow through the valve. The stem and valve disc move downwards when the handwheel is rotated clockwise. The valve seat and the disc create a tight seal that prevents any fluid flowing through the valve.

Figure: Working of a duplex globe valve.

Advantages of duplex globe valve

- These valves are excellent in shut-off and throttling.

- They operate faster.

- They have tight closure.

Disadvantages of duplex globe valves

- These valves are heavy.

- They have high flow resistance.

Duplex gate valve

This duplex valve is used to shut off fluid flow using a wedge or rectangular gate. An actuator or handwheel controls the gate through a component known as a stem/shaft. This valve is one of the isolation valves commonly used in industrial systems. It is preferred due to its simple mechanics, making repair easier. There are various types of this valve, including duplex knife gate, wedge gate, parallel slide gate, rising stem, and non-rising stem gate valve, among others. Each type has its preferred area of use and its advantages and disadvantages.

Figure: Duplex gate valve.

How does a duplex gate valve work?

This valve operates by moving the gate up and down to open and close fluid flow respectively. When the valve operator rotates the handwheel in the anticlockwise direction several times, the valve stem rotates in the same direction. This rotation creates a linear upward movement on the valve gate. As such, the gate moves up, leaving the flow passage open. When the valve operator rotates the handwheel clockwise, the valve gate moves down and creates a tight seal with valve seats. In this condition, the valve is closed, and no fluid flows through.

Figure: Working of a duplex gate valve.

Advantages of duplex gate valves

- These valves have a simple design.

- They are easy to repair.

- They have low-pressure drops when fully opened.

- They are bi-directional valves.

Disadvantages of duplex gate valves

- They are not ideal for throttling.

- They are prone to noise and vibration relative to other valves.

Duplex butterfly valve

This is a special version of the valve that operates by rotating the handwheel for a quarter turn to open and close fluid flow. It is one of the easiest valves to operate. This valve uses a disc to control fluid flow. Duplex valve manufacturers design this valve such that the disc is installed at the center of the flow path. This design makes the valve simple and easy to repair. It also makes the valve light in weight since it uses a small amount of material and a thin design. Various types of this valve include rotary, lug-style, concentric, wafer, and eccentric valves.

Figure: Duplex butterfly valve.

How does a duplex butterfly valve work?

When the operator rotates the handle or handwheel in the counterclockwise direction for 90o degrees, the valve disc rotates to leave the fluid passage open. The disc is connected to the handwheel through a component known as a stem or shaft. This shaft transmits the rotary force from the handle to the disc. When the operator turns the handle in the clockwise direction for another quarter turn, the disc rotates to make a tight seal with the valve seat and thus closes fluid flow. When the valve operator needs the valve to regulate flow rate, the handle is rotated slightly for an angle less than 90o degrees, allowing some flow through the valve. Duplex valve manufacturers recommend using this valve for throttling at low-pressure applications.

Figure: Working of a duplex butterfly valve.

Advantages of duplex butterfly valves

- These valves have small sizes and hence light in weight.

- They are suitable for fluids with sludge and slurries.

- They are easy to operate.

- They are easy to install, clean, and repair.

Disadvantages of duplex butterfly valves

- The valve disc is mounted on the flow area, which increases flow resistance and, thus, pressure loss.

- Excellent sealing is hard at high-pressure applications.

Duplex plug valve

This is the valve that uses a conical or cylindrically tapered plug. The plug is rotated inside the valve to regulate flow. The plug comes with one or more through holes at its center. The fluid flows through these holes when the valve is opened. This type of valve is simple and reliable in high-pressure applications. The valve operates using a handwheel, pneumatic or electric actuator. Duplex valve manufacturers produce various types of valves under this category, including expanding valves, non-lubricated valves, lubricated valves, and multi-port valves.

Figure: Duplex plug valve and its components.

How does a duplex plug valve work?

This valve operates by turning the handwheel for just a quarter turn. The valve disc is connected to the handwheel through the valve stem. When the handwheel is rotated counterclockwise for an entire quarter turn, the valve disc rotates for 90o degrees. This rotation forces the plug through-hole to align with the pipe connected to the valve and hence fluid flows through. When the handwheel is rotated opposite for another full quarter turn, it causes the disc to rotate and aligns the plug hole perpendicular to the flow direction. In this state, the valve is closed, and thus no fluid flows through since the plug and the valve seats mate to form a tight seal.

Figure: Working of a plug valve.

Advantages of duplex plug valves

- These valves are leakage-proof.

- They have high strength suitable for high-pressure applications.

- They only need a quarter turn of the handwheel to open/close.

- They can be repaired and cleaned while on the piping system.

Disadvantages of duplex plug valves

- High friction is involved when rotating the plug.

- The conical and taper shapes increase flow resistance and pressure drop.

Duplex check valve

This special type of duplex valve operates automatically to prevent fluid from flowing in the reverse direction. Unlike all the other valves mentioned above, this valve does not need a handwheel or actuator. It uses a disc or ball component to open or close the flow. This valve is highly recommended for use where reverse flow may cause fluid contamination, such as in water supply, boiler systems, foods and beverages, and pharmaceuticals. Duplex valve manufacturers have various types of this valve, such as swing check valve, spring loaded valve, ball check valve, and lift-foot valve, among others.

Figure: Duplex check valve.

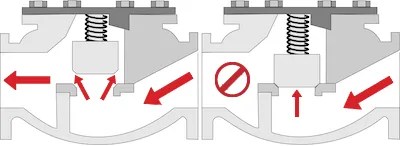

How does a duplex check valve work?

This valve is not operated using a handwheel or actuator. Duplex valve manufacturers design this valve to open and close based on the pressure difference between the upstream and downstream sides. When the upstream pressure is more than the pressure on the downstream side or when the pump is working, the fluid pressure acts on the valve disc forcing it to open. Once opened, fluid keeps flowing through the valve until the pump stops or the upstream pressure reduces. Once the pump stops or upstream pressure reduces below downstream pressure, the fluid attempts to reverse the flow direction. However, the valve disc closes immediately and prevents any reverse flow.

Figure: Working of a duplex check valve.

Advantages of duplex check valves

- This valve is cheaper relative to other valves like gate and globe valves.

- It does not need a handwheel or actuator.

- It is highly reliable.

- No reverse flow.

- Low fluid flow resistance.

Disadvantages of duplex check valves

- It is a unidirectional valve.

- Not suitable for pulsating flows.

Applications of duplex valves

Duplex valves are used in many industrial applications because of their numerous advantages over other valves. Typical applications of this valve include:

- Oil and gas industry.

- Paper and pulp manufacturing.

- Chemical and petrochemical applications.

- Foods and beverages.

- Pharmaceutical industries.

- Sewage and wastewater treatment.

- Municipal and domestic water transportation.

- Mining applications.

- Steam power plants.

- Firefighting applications.

- Marine applications.

Advantages of duplex valves

- These valves are versatile in size and thus suitable for small and large flow rates.

- They are versatile in applications as they have been used in almost all industrial applications.

- They have excellent corrosion resistance.

- They are strong, suiting them for high-pressure and high-temperature applications.

- Duplex valves are resistant to abrasive wear.

- These valves are highly durable.

Disadvantages of duplex valves

- The duplex material is quite expensive, and thus the valve.

- They are heavy.

Troubleshooting duplex valves

The handwheel/handle is hard to operate

- Damage on the valve stem. Repair or replace the stem.

- Dirt on the valve stem. Clean off the dirt.

The valve does not close completely

- Dirt on the valve seats. Clean off the dirt.

- Worn out seats. Replace the valve seats.

- Worn out disc. Replace the valve disc.

Fluid leakage inside the valve

- Damaged or worn-out seats. Replace valve seats.

- Damaged or worn-out disc. Replace the valve disc.

Leakage between the valve and the pipe

- Worn out gasket. Replace the gasket.

- High flow pressure. Replace the valve with a high-rated valve. The valve should be used at the flow rate and pressure recommended by the duplex valve manufacturer.

The valve vibrates a lot

- High flow rate. Use the valve at the recommended flow rate and pressure.

- The valve is not fully open. Open the valve fully.

Summary

A duplex valve is a type of valve that is made of a duplex steel. Duplex steel has superb mechanical and chemical properties, making it one of the preferred alloys for industrial valves. This valve operates manually or automatically. The manual valve uses a handwheel or hand lever, while the automatic one uses a pneumatic or electric actuator. The valve uses a disc or ball component to control fluid flow. A component known as a stem connects the handwheel/actuator to the valve disc/ball. When the handwheel is rotated, the disc/ball is moved to allow or close the fluid flow.

Duplex valve manufacturers have produce various types of valves that include gate, globe, check, butterfly, and plug valves, among others. The various industries where these valves are used include mining, paper and pulp, water supply, sewage and wastewater treatment, oil and gas, chemicals, foods and beverages, pharmaceuticals, marine, and firefighting systems, among others. The advantages of this valve are high strength, versatility in size and application, durability, and corrosion resistance.