hide

What is a high-performance butterfly valve?

Components of a high-performance butterfly valve

Valve body

Stem

Hand wheel/actuator

Disc

Seat

Gasket

Packing

How does a high-performance butterfly valve work?

Types of a high-performance butterfly valve

Double flanged high-performance butterfly valve

Manual high-performance butterfly valve

Actuated high-performance butterfly valve

Applications of high-performance butterfly valves

Advantages of high-performance butterfly valves

Disadvantages of high-performance butterfly valves

Troubleshooting high-performance butterfly valves

Fluid leakage through valve-pipe connection

Fluid leakage through the stem

Internal fluid leakage

Valve is hard to operate

Summary

What is a high-performance butterfly valve?

A high-performance butterfly valve is a valve in which the stem is not collinear to the disc center-line but rather offset from the center. There are two offset categories of this valve that is the double offset and triple offset types. The use of offset design helps to enhance uniform tight shut-off against the valve seat and also reduce wear due to friction. The high-performance butterfly valve can be used for shut-off and throttling fluid flow applications. High-performance butterfly valve manufacturers produce this valve to handle different fluids from general fluid flow applications to viscous and corrosive fluids. The corrosive fluids can be gases or steam. High-performance butterfly valves are mostly of large sizes like 60-inch diameter. These valves are made of strong materials like carbon steel and stainless steel. High-performance butterfly valve manufacturers design these valves to operate in a wide range of temperatures from -28 oC to 500 oC. The choice of the operating temperature depends on the materials used to make the valve. High-performance butterfly valves are operated either manually or through actuators. The operation of these valves follows a quarter turn principle used in ball valves. This is the principle in which the handle is rotated for 90o degrees only to either open or close the valve as necessary.

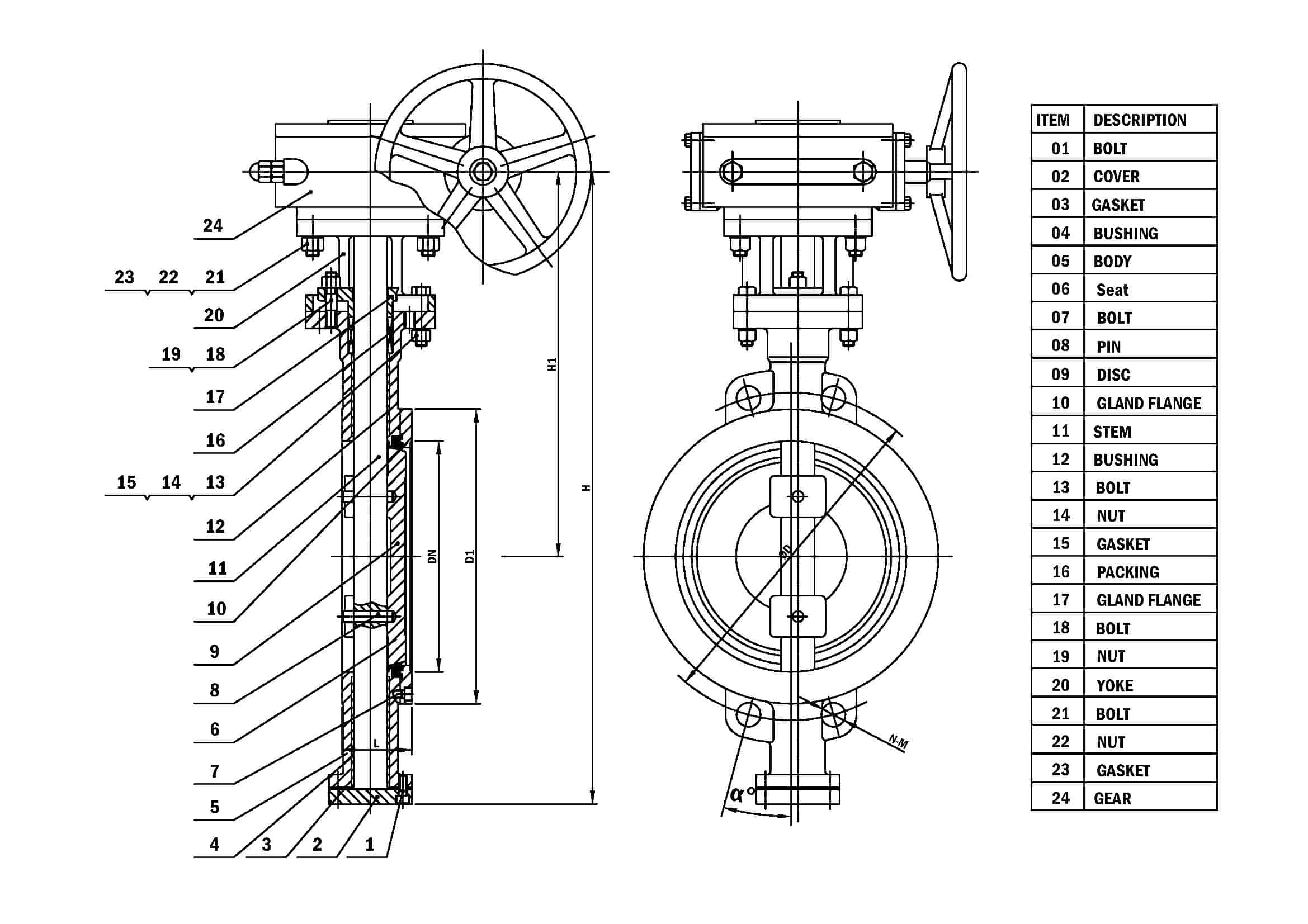

Figure: High performance butterfly valve.

Components of a high-performance butterfly valve

Valve body

This is the component tasked with housing internal parts. The body is usually made very strong relative to other parts to ensure it can support weight and prevent valve damage due to impact from falling objects. The high strength also helps the valve to withstand fluid pressure. Some of the materials that high-performance butterfly valve manufacturers use to make the body are nickel alloy, stainless steel, ductile iron, and carbon steel among others.

Stem

This is a metallic component that connects the handle or actuator to the valve disc. The stem works by rotating when the handle is rotated. As such, the work of the stem is to transmit the torque applied on the handle by the valve operator or from the actuator to the disc.

Hand wheel/actuator

The handwheel is used in manual high-performance butterfly valves while the actuator is used in automatic ones. The work of this component is to provide the power needed to close or open the valve. The handle is connected to the valve closing and opening element known as the disc via the stem.

Disc

This is the part of a high-performance butterfly that allows and blocks fluid flow as necessary. The disc gets its power to start and stop the valve from the handwheel or actuator.

Seat

This component is placed inside the valve body and it provides a surface where the disc seats when the valve stops. The seat ensures no fluid can leak once the valve closes. The material used by high-performance butterfly valve manufacturers to make the seat is very important as it determines where that valve can be used in terms of temperature and media type.

Gasket

This is a seal placed between the valve and pipe mating surfaces to prevent fluid leakage. The gasket is maintained in its position by high strength created by valve bolts and nuts.

Packing

This is a seal component placed between the stem and the body to prevent fluid leakage along the stem.

Figure: Components of a high performance butterfly valve.

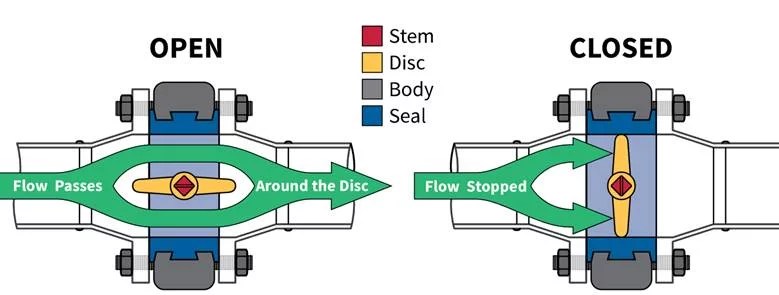

How does a high-performance butterfly valve work?

This valve operates using a handwheel/hand lever or actuator. A handwheel or hand lever is used in manual valves and it is where the operator applies force to start and stop the valve. The actuator is used in automatic valves to provide the torque needed to start and stop the valve. To open a high-performance butterfly valve, the stem is rotated for 90o degrees in the anticlockwise direction by the torque applied by the actuator or on the handwheel as necessary. At the same time, the disc rotates at the same 90o degree angle. This rotation forces the disc to align itself parallel to the fluid flow where it leaves an unobstructed path. To close the valve, the stem and disc are turned in the opposite direction (clockwise) for a 90o degrees angle only. This aligns the disc perpendicular to the flow path and then it stops any fluid crossing through the high-performance butterfly valve. These valves are also used in throttling applications in which the valve disc is rotated slightly to allow some amount of fluid to flow. High-performance butterfly valve manufacturers recommend use of these valves in throttling applications if only there is a low-pressure drop.

Figure: Working of a high performance butterfly valve.

Types of a high-performance butterfly valve

Double flanged high-performance butterfly valve

This is a high-performance butterfly valve that is designed with two flanged ends. The flanged ends are at the inlet and outlet sides of the valve. These flanged ends have holes. This type of valve is connected to a pipe that has flanged ends of equal diameter as well as the same sized number of holes. High-performance butterfly valve manufacturers produce this type of valve for use where the fluid pressure is very high. With this type of valve, fluid leakage is hard to occur due to the tight seal enhanced by the bolts and nuts used as well as the gasket placed between the pipe and the valve. However, this type of valve is heavy compared to other valves. High weight is due to the several bolts and nuts and flanged ends.

Figure: Double flanged high performance butterfly valve.

Manual high-performance butterfly valve

This is a high-performance butterfly valve that is operated manually. High-performance butterfly valve manufacturers produce this valve to operate using a handwheel that has a gear system. The gear system is enclosed in a gearbox. The gear system is meant to change the direction of rotation of torque from the handwheel to the valve stem and finally to the disc. This is because in most cases the torque from the handwheel and the valve stem are perpendicular to each other. As such, a bevel gear system is used to change horizontal torque to the vertical direction. The gear system also helps to multiply the torque applied by the valve operator so that it becomes easy to open and close the valve. Manual high-performance butterfly valves are cheaper relative to the actuated ones. However, these valves cause a lot of fatigue to the valve operator, especially where a lot of torque is needed to start and stop the valve as well as where valve operation is frequent.

Figure: Manual high performance butterfly valve.

Actuated high-performance butterfly valve

This is a high-performance butterfly valve that is operated by use of actuators. The actuator is placed on top of the valve. This valve makes piping operation easy and cheaper as it can automatically operate without the need of a valve operator. This helps to cut down the costs incurred by having a valve operator. Actuated valves can also be remote controlled to thus saving on time. The work of the actuator is to provide the power needed to start and stop the valve. High-performance butterfly valve manufacturers produce three types of these actuated valves which are:

- Hydraulic high-performance butterfly valve. This valve uses an actuator that operates by using hydraulic fluid. This valve is suitable for use in applications that need a lot of torque since the use of the hydraulic fluid which is incompressible helps to enhance high torque output. However, this valve is affected by high temperatures and thus it is suitable for use in low-temperature applications.

- Pneumatic high-performance butterfly valve. This is a valve that uses compressed air to operate. The pneumatic actuator used makes this valve suitable for different applications from low to high temperature and very clean to dirty applications.

- Electric high-performance butterfly valve. This valve uses an electric actuator to start and stop the fluid flow. This valve is suitable for use in both low and high temperatures. The operation of this valve is possible in almost all industrial applications because of electricity availability.

Figure: Actuated high performance butterfly valve.

Applications of high-performance butterfly valves

- These valves are used in municipal water supply and water treatment applications.

- They are used in mining operations.

- High-performance butterfly valves are used in foods and beverage processing as they can be easily cleaned. Also, these valves hardly get clogged.

- They are used in steam power generating plants to help control the flow of steam and water.

- High-performance butterfly valves are used in the manufacturing of different chemicals.

- They are used in the paper and pulp manufacturing industries.

- These valves are used in the refinery of petroleum products.

- High-performance butterfly valves are used in fire-fighting applications.

Advantages of high-performance butterfly valves

- High-performance butterfly valves operate very fast compared to gate and globe valves.

- These valves have short-length bodies which makes them occupy small installation space.

- High-performance butterfly valves are cheaper relative to other high-performance valves.

- These valves are versatile as their design allows them to work in different industrial applications.

- They are free from fluid leakage.

- High-performance butterfly valves can be operated manually or by use of actuators as necessary.

- These valves have high strength allowing them to work in high pressure and high temperature.

- They can be used as shut-off or throttling valves.

- These valves are of simple and compact design.

- They are easy to clean, install and repair.

- They are of low weight relative to other valves.

- Their maintenance intervals and cost are lower compared to other valves.

Disadvantages of high-performance butterfly valves

- These valves are expensive compared to other butterfly valves.

- These valves open while the valve disc is in the fluid flow path which reduces fluid flow pressure.

- High-performance butterfly valves are suitable for throttling use only where fluid pressure drop is low.

- The sealing of these valves is poor compared to that of other valves like ball valves.

Troubleshooting high-performance butterfly valves

Fluid leakage through valve-pipe connection

- Loose bolts and nuts. Tighten the bolts and nuts to attain the torque recommended by the high-performance butterfly valve manufacturer.

- Damaged or worn-out gasket. Replace the gasket.

Fluid leakage through the stem

- Worn-out or damaged gland packing. Replace the packing.

- Worn-out O-rings. Replace the O-rings.

Internal fluid leakage

- Worn out seats. Replace the seats.

- O-rings are worn out. Replace the O-rings.

- Dirt in the valve. Open the valve and clean off any dirt.

Valve is hard to operate

- Foreign materials in the valve. Open the valve and remove any foreign materials. Clean all the internal components.

- Corrosion in the valve. Open the valve and clean off any corrosion.

Summary

High-performance butterfly valves are designed such that the stem is not collinear to the valve disc centerline but at some offset distance. The offset design criteria helps to ensure uniform tight shut-off and reduce wear due to friction. High-performance butterfly valve manufacturers design these valves for use in high-pressure applications as they can work without causing leaking. These valves are also meant for use in high and low-temperature applications depending on which materials have been used to make the valve components. High-performance butterfly valves are used for shut-off and throttling applications. However, these valves are suitable for use in throttling fluid flow if there is low-pressure drop. These valves operate by making a 90o degree rotation of the disc to open and close the fluid flow. This makes the valve very fast in operation compared to other valves.

High-pressure butterfly valve manufacturers have various types of this valve which include double flanged high-performance butterfly valve, manual high-performance butterfly valve, and actuated high-performance butterfly valves among others. These valves are used in applications such as petroleum refineries, fire-fighting, water supply, chemicals, mining, foods and beverages, steam power plants, and paper and pulp manufacturing among others. Advantages of these valves include fast operation, relatively small installation space, lightweight, simple and compact design, and easy to repair, install, and clean.